Recommendations

CNC Machining Design for Manufacturing: Expert Technical Guide

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!The depth of cavities and grooves is typically limited by the cutting tool diameter us...

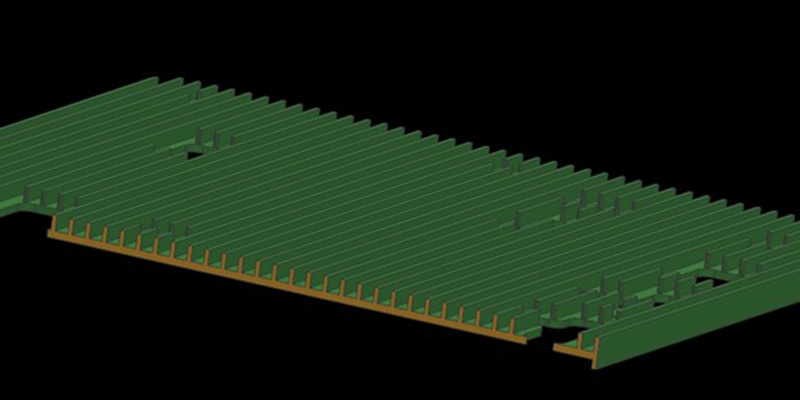

How to Prevent Warping and Deformation in Large and Thin-walled Shell Parts During CNC Machining?

Large, thin-walled shell parts are easy to warp and deform during machining. In this article, we will introduce a heat sink case of large and thin-walled parts to discuss the problems in the regular machining process. In addition, we also provide an optimized process and fixture solution. Let’s get to it! The case is about a shell part made of AL6061-T6 material. Here are its exact dimensions. Overall Dimension: 455*261.5*12.5mmSupport Wall Thickness: 2.5mmHeat Sink Thickness: 1.5mmHe...

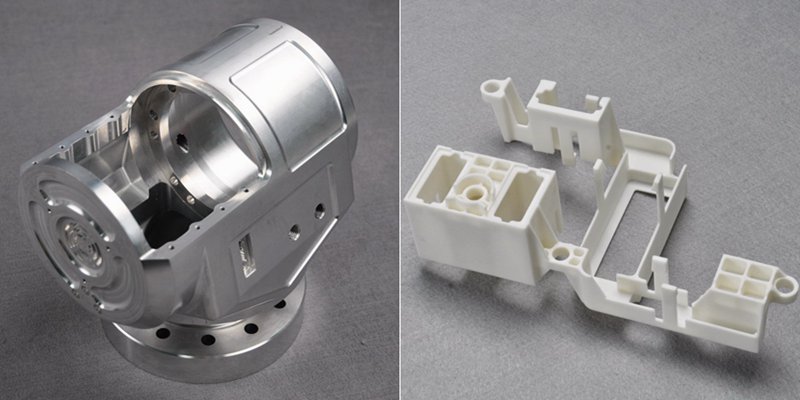

How to Machine Polyhedral Aluminum Parts by Designing Process Routes and Fixture?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

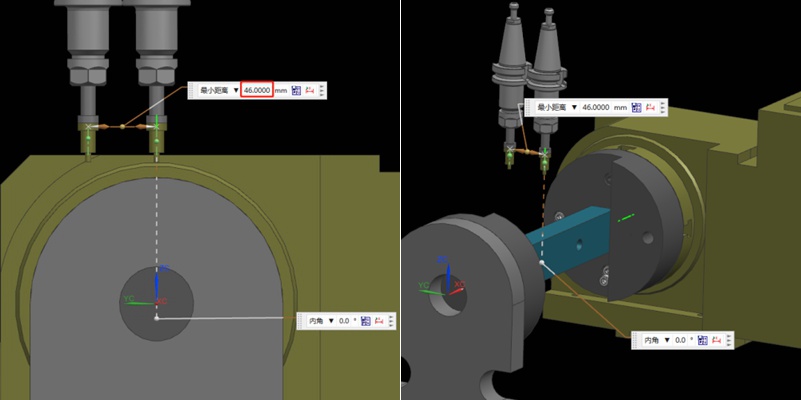

How to Determine the Rotation Center of Rotary When Operating a 4-axis CNC Machine?

Nowadays, a four-axis rotary table is a common piece of equipment in the machine shop. In order to complete the machining of multiple faces in one coordinate, the programming coordinates must be synchronized with the coordinates of the rotary table. In this article, we will share a method to determine the rotation center of a 4-axis rotary table.Here, we show a 4-axis rotary table that rotates around the X-axis of a machine tool, where the axis of rotation is called the A-axis. In a word,...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd