A Brief Introduction to Turning

Turning is essentially a cutting operation where a sharp cutting tool shapes a rotating workpiece by removing material from its surface. The tool moves along the surface of the workpiece in a specific pattern to achieve the desired shape.

Primarily, turning creates cylindrical or conical shapes due to the rotating motion of the workpiece. However, modern CNC turning technologies can also create more complex geometric features.

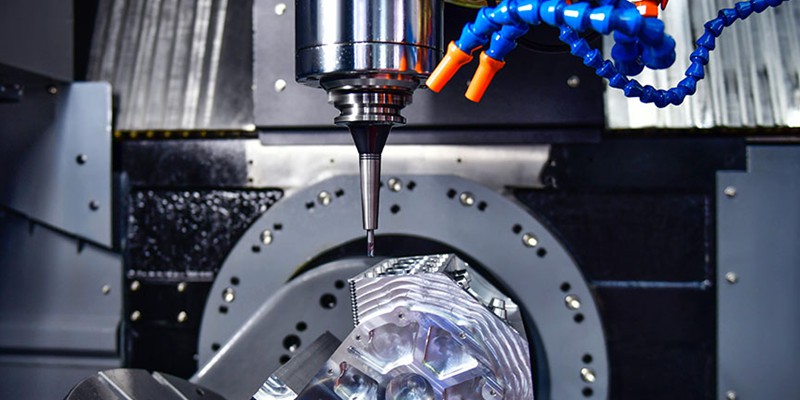

A lathe machine typically performs turning operations. It may be a standard engine lathe, turret lathe, or a CNC lathe. Nowadays, advanced CNC machining centers like turn-mills can also achieve precise geometries for turning.

Step turning and taper turning are two common types of turning operations. Let us now take a deep insight to these topics.

What is Step Turning?

The step turning process is the more fundamental and simpler process in the step turning vs taper turning comparison. In step turning, a lathe machine is used to create multiple steps (sections with different diameters) along the length of the rotating cylindrical workpiece.

Each step is a section with a constant diameter. This indicates that the feed direction of the lathe-cutting tool is always parallel to the axis of the workpiece.

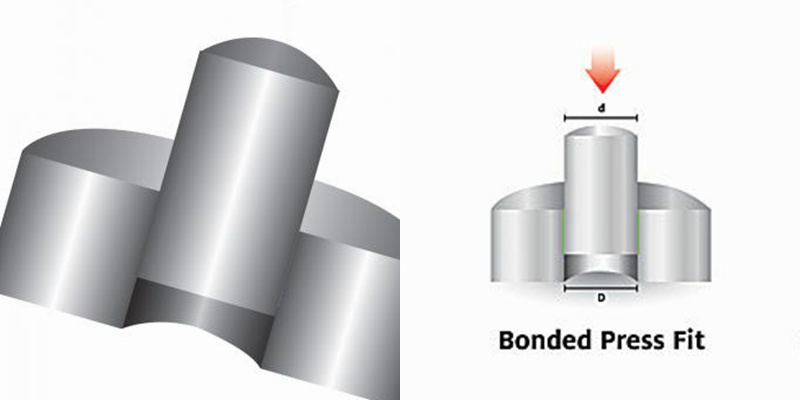

Since the appearance of sections with different diameters resembles that of ‘steps’ as in a staircase, the name ‘step turning’ has become common. The figure below shows a typical multi-step shaft with the relevant terminologies.

The final workpiece may have any number of steps, depending on the design. These steps may have numerous applications like providing seats for mating components like sleeves, shoulders for locating bearings, or for aesthetic purposes.

How Does the Step Turning Process Work?

The step turning process is fairly straightforward but requires patience. Generally, step turning starts with a uniform round stock mounted in the machine.

Then, an initial rough cut is taken to achieve a uniform diameter across the stock’s length and to remove any uneven features on the surface.

Afterward, machinists perform step turning in a gradual manner, decreasing the diameter of each section in multiple steps until they achieve the correct diameter. For each subsequent step, the cutting tool should ensure correct alignment and dimensions.

In the end, it is good practice to add a finishing cut. This helps achieve a fine surface finish and precise control over dimensions.

What is Taper Turning?

Let’s now move to the second part of our discussion on step turning vs taper turning. The taper turning process creates a surface with a taper, which means that the diameter of the workpiece changes gradually along its length. The final workpiece has a conical shape, which contrasts with step turning, which has sharp steps and straight surfaces.

Taper turning can have various types. A summary of each is as follows:

- External Taper: External tapers are on the outside surface of the workpiece, as shown in the figure above.

- Internal Taper: Internal tapers are created on the inner surface of hollow workpieces, typically with a boring tool.

- Straight Taper: The tapered surface is straight and has no curvature. In other words, straight tapers have a consistent taper angle along the length of the cut.

- Variable Taper: Variable tapers are not straight. They feature curves and splines by using a variable taper angle.

How Does the Taper Turning Process Work?

The taper turning process is a bit more complex when it comes to comparing step turning vs taper turning. Machinists need to consider more factors when planning a taper cut and practice more care.

Generally, the points related to workpiece mounting, rough cuts, and finishing allowances are the same as step turning. There are, however, other factors to consider as well.

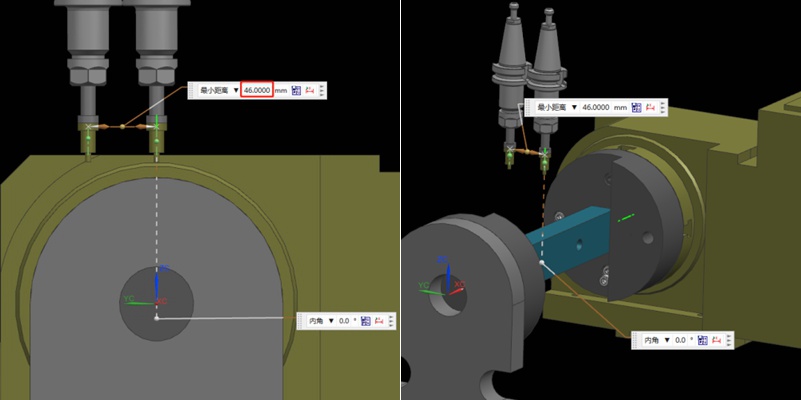

First and foremost, the taper angle is calculated. For this, let us look at the figure above. It shows the final shape of the workpiece with a taper. The terms are as follows:

- α = Taper angle

- L = Length of the tapered portion of the workpiece

- D = Maximum diameter at the larger end of the taper

- d = Minimum diameter at the smaller end of the taper

The following formula computes the taper angle:

This is the angle the cutting tool must move with respect to the axis of the rotating workpiece.

After computing the taper angle, machinists choose a suitable taper turning method. There are several techniques to perform taper turning. The most common taper turning process methods are as follows:

- Taper Turning Attachment: Machinists use a special attachment on the lathe machine that allows the feed direction to be at an angler equivalent to the taper angle.

- Offset Tailstock: The tailstock of the lathe machine is slightly shifted to one side, tilting the workpiece to an angle. By fine-tuning the tailstock offset, the correct taper angle can be achieved.

- Compound Slide: The angle of the compound rest of the lathe machines is also adjustable. Generally, there is also an angle gauge embossed in the compound rest base. In many cases, this is the most convenient and quick way to perform taper turning during manual machining.

- Form Tool: This method utilizes custom tool designs (form tools) with an inclined cutting edge. The inclination angle equals the taper angle. In this technique, the feed direction is perpendicular to the workpiece axis.

Key Differences Between Step Turning and Taper Turning

The step turning process and taper turning process are both lathe operations with a similar machine and tool setup. However, as we just saw, there are various differentiating points between the two. An expert engineer and technician should be well-versed in these differences to fully understand when and how to use either type of turning process.

Workpiece Geometry

The most significant difference between step turning and taper turning is in terms of geometry. Step turning workpieces have flat, stepped profiles while taper turning creates conical profiles.

In a variable taper turning process, the slope of the profile features curves, making it a more versatile process than step turning.

Tool Movement

The feed direction of the cutting tool differs between both turning processes. In a step turning process, the tool moves parallel to the axis of the workpiece. The distance of the cutting tool tip from the workpiece axis is equivalent to the diameter of the shaft’s step.

In taper turning, owing to the requirement of cutting along the taper angle, the cutting tool moves at an angle to the workpiece axis. In this case, since the tool moves at an angle, the distance between the cutting tool edge and the workpiece axis is constantly varying. However, it remains between the maximum and minimum diameter of the taper section.

Tool Setup

The tooling setup and executing method are also quite different when it comes to comparing step turning vs taper turning. The cutting tool setup is very simple in step turning, with the tool just firmly mounted in any suitable orientation in the tool mounting device.

For taper turning, a lot more care and decision-making is needed. To begin with, there are several methods to machine a taper. In the previous sections, we discussed some of the common taper turning methods.

Moreover, since the taper angle is another parameter in the machining process, it introduces an additional source of inaccuracy. Each method has its own tolerance range for the taper angle. Generally, methods requiring manual adjustments like the tailstock offset method or compound slide method are more inaccurate than others like using form tools or CNC machines.

Post Processing

The post-processing for step turning and taper turning components is also different. The taper turning process generally produces a single surface with a single cutting action. This produces a finer surface finish which is convenient to polish.

In a step turning process, there are several surfaces. Each step adds two orthogonal surfaces, one parallel to the axis of rotation and one perpendicular to it. This kind of geometry is typically prone to inconsistencies in terms of surface finish. Especially, at the transition points, that is the edge where a step starts or ends, is sometimes hard to produce as a perfect corner due to the nose radius of the cutting tool.

Common Applications of Step Turning and Taper Turning

Regardless of the various comparison points between step turning vs taper turning, they are both important machining processes in manufacturing.

| Industry |

Step Turning |

Taper Turning |

| Automotive |

Straight shafts: axles, pins, gearbox shafts |

Engine components: valve stems, studs |

| CNC Machines |

Spindle shaft, tool shanks |

Precision taper seats for tool holders, collets, drawbars |

| Medical |

Medical device construction: surgical tools, support canes |

Dental drills, needles, orthopedic pins |

| Oil and Gas |

Pump shafts, pipes with multiple sections |

Nozzles, tapered drill bits |

| Electronics |

Motor shafts, mounting sleeves, actuators |

Connecting pins, solder tips |

شركة ShenZhen Washxing Technology Co.,Ltd.

شركة ShenZhen Washxing Technology Co.,Ltd.