Συστάσεις

Σχεδιασμός μηχανουργικών κατεργασιών CNC για την κατασκευή: Τεχνικός οδηγός εμπειρογνωμόνων

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!The depth of cavities and grooves is typically limited by the cutting tool diameter us...

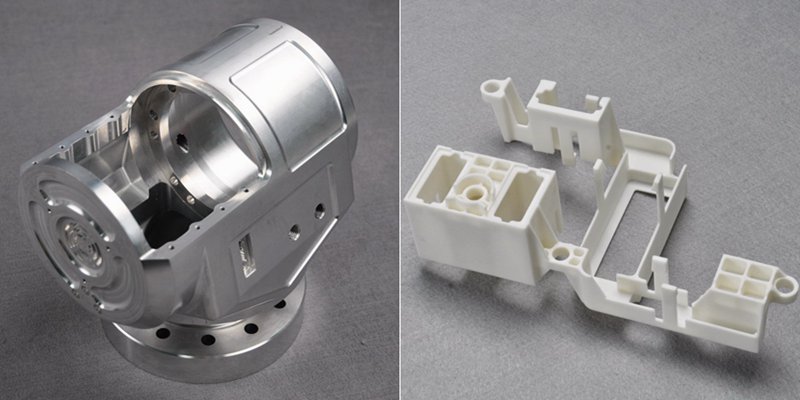

Παραγωγή και κατασκευή γεφυρών: Μπριζόλα: Βασικά στάδια και οφέλη

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

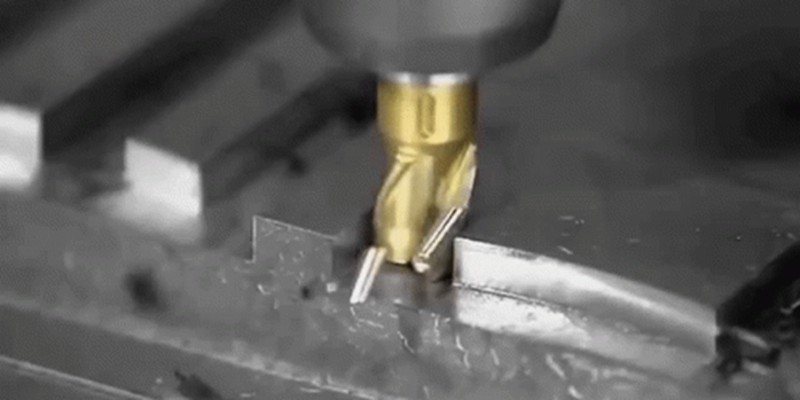

Αιτίες και λύσεις για τα σημάδια εργαλείων στην κατεργασία μετάλλων

Precision metal parts are often manufactured using various precision machining technologies, with CNC machining being a common method. Usually, precision parts typically demand high standards for both dimensions and appearance. Therefore, when using CNC machining metals such as aluminum and copper, the occurrence of tool marks and lines on the finished product’s surface is a concern. This article discusses the reasons that cause tool marks and lines during the machining of metal products....

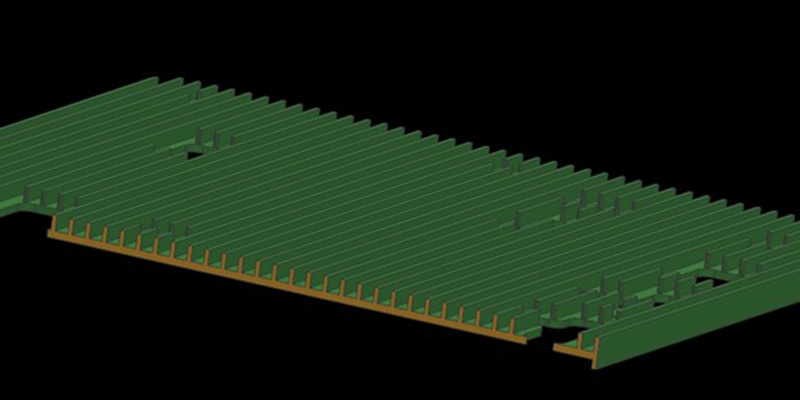

Πώς να αποτρέψετε τη στρέβλωση και την παραμόρφωση σε μεγάλα και λεπτότοιχα εξαρτήματα κελύφους κατά τη διάρκεια της κατεργασίας με CNC;

Large, thin-walled shell parts are easy to warp and deform during machining. In this article, we will introduce a heat sink case of large and thin-walled parts to discuss the problems in the regular machining process. In addition, we also provide an optimized process and fixture solution. Let’s get to it! The case is about a shell part made of AL6061-T6 material. Here are its exact dimensions. Overall Dimension: 455*261.5*12.5mmSupport Wall Thickness: 2.5mmHeat Sink Thickness: 1.5mmHe...

ShenZhen Washxing Technology Co., Ltd.

ShenZhen Washxing Technology Co., Ltd.