Πώς να επεξεργαστείτε πολυεδρικά εξαρτήματα αλουμινίου σχεδιάζοντας διαδρομές διαδικασίας και εξαρτήματα;

Συστάσεις

Παραγωγή και κατασκευή γεφυρών: Μπριζόλα: Βασικά στάδια και οφέλη

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

CNC Acrylic Machining: All You Need To Know Machined Acrylic Parts

Today we are going to look at the manufacturing processes of acrylic polymer or optical prototyping. It is one of the most widespread plastics all over the world and a prominent competitor to glass and polycarbonate. Due to the fact that acrylic parts are used in a lot of industry areas, it seems a good idea to look into its manufacturing processes, specifically CNC acrylic machining since that is the process that is present in almost any kind of acrylic production. In this article, we wi...

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

Αιτίες και λύσεις για τα σημάδια εργαλείων στην κατεργασία μετάλλων

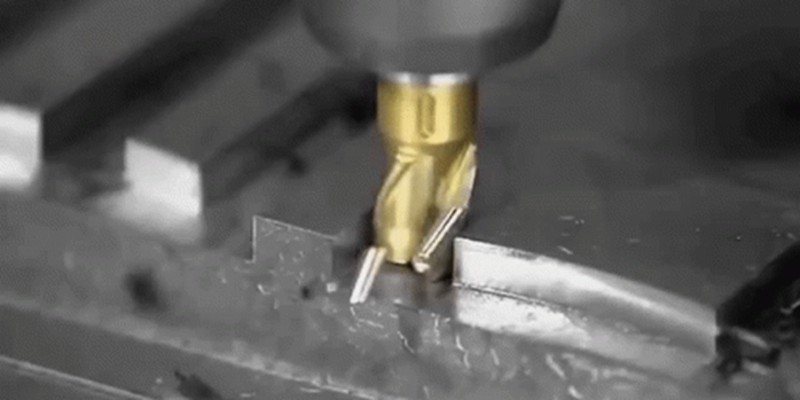

Precision metal parts are often manufactured using various precision machining technologies, with CNC machining being a common method. Usually, precision parts typically demand high standards for both dimensions and appearance. Therefore, when using CNC machining metals such as aluminum and copper, the occurrence of tool marks and lines on the finished product’s surface is a concern. This article discusses the reasons that cause tool marks and lines during the machining of metal products....

ShenZhen Washxing Technology Co., Ltd.

ShenZhen Washxing Technology Co., Ltd.