How To Create A Prototype With Steps: An Expert Guide

What Is A Prototype?

A prototype is an early version or physical model of a product idea that manufacturers can test and refine before investing in mass production. It acts as a product template and provides a practical approach to understanding a product’s appearance and function before production.

When developing a product, product teams create a product prototype to test the product’s usability, design, and performance, gather user feedback, identify potential issues in the early stages, and identify possible improvements. More so, designers develop a prototype to get a product to market faster and ensure the product meets the needs of end users.

Why Create A Prototype?

There are two main types of prototypes: physical and virtual. A physical prototype is an actual, three-dimensional version of the product being designed. They are often used to test the actual functionality and appearance of a product.

A virtual prototype, on the other hand, is a computer-generated model of the product. They can be used to analyze things like various parameters and assemblies. The following is why you need to make a prototype.

Test and Improve the Functionality of Your Design

The first prototype is usually the most basic version of your product idea. This is the prototype that you use to test the feasibility of your product or idea.

Many times, your idea works in theory. It’s not until you start actually creating it that you come across a flaw in your thinking. That’s why an important reason to develop the first prototype is to test the functionality of your idea. You will never know the problems and challenges of design until you start to take your ideas from theory to reality.

Gain Credibility and Professional Recognition

When you meet any professional with a prototype in your hand — from your own lawyer to potential investors — you set yourself apart from dozens of people with vague ideas. Instead, you’ll be seen as a goal-oriented professional, not just an inventor with a potential idea.

Evaluate Material Performance and Cost Efficiency

For example, you might want to use metal originally — until you test its prototype and realize that plastic performs better with fewer costs in your particular application. Making prototypes will help you determine the best material.

Enhance Product Presentation and Decision-Making

When it comes to product display, prototyping is essential. A prototype is an early sample, model, or release of a product built to test a concept or process. It allows prototype designers to make changes and adjustments before mass production begins.

Step-By-Step Process For How To Make A Prototype

Prototype manufacturing contributes significantly to transforming ideas into market-ready products through a series of steps that ensure the product’s success. Standard steps on how to create a product prototype include:

1. Conduct Research

Researching similar products helps to understand your idea and make it more unique before starting. It will help you identify existing products, how they are built, the materials used, and how they work.

Furthermore, market research helps to determine your potential customers, competitors, and target market. This step in the prototype-making process ensures your concept is practical as it is innovative, and discovers potential issues and gaps in the product market.

2. Create Sketches of Your Design Idea

After your research, you must know how to develop creative sketches of your concepts. Create your sketches on paper or use software, including views from different angles and defined design requirements.

Begin with rough sketches to consider different ideas, then optimize them into detailed drawings. You can also visualize your concept and indicate its features, balancing visual appeal with usability.

3. Creating a Virtual Model

Before making a physical prototype, you must develop a digital version of your design using 3D modeling software like Catia, Solidworks, or UG. It allows you to convert your product design from mere sketches to 3D models and examine how the product will look and function without creating it. With CAD software, you can digitally visualize and refine the design for potential issues before proceeding.

4. Perform Feasibility Analysis

Check if your design can be built with available materials and the chosen process, and that the production costs fall within budget. You must assess the design options for their technical viability and examine their manufacturing requirements. This feasibility analysis provides a clear picture of the idea for your brand work as you progress.

5. Generate a Proof of Concept

With a proof of concept, you can easily demonstrate how your product will work because it helps to test the feasibility of the design. Although it might not possess the exact look as the final product, it focuses on the form factor and dimensions of an idea for a product. It must possess moving or mechanical parts from the design, so you can examine how each part functions in an assembly. More particularly, it helps to detect flaws early and ensure you build a prototype that fits and functions as intended.

6. Create the Physical Prototype

You can create a working prototype after verifying the proof of concept. Use suitable tools and manufacturing processes to create a product prototype based on the updated design. This prototype must integrate both functionality and appearance to demonstrate how it will function in real life.

7. Test and Validate the Prototype

You must test the created prototype thoroughly to ensure it meets the aesthetic, performance, and functionality requirements. Examine for performance, usability, and durability under different conditions. Aside from saving time and money in the long run, these tests help identify areas that require refinement early and reduce the risk of failure.

8. Collect Feedback and Refine Design

Have credible sources, such as industry experts, potential users, or team members, examine the prototype to collect their opinions and ask what they like about it, what needs improvement, and if the product meets their needs. This feedback is essential in making necessary changes to improve the design and make a production-ready prototype before committing to full-scale production.

Process Technologies Involved In Creating A Prototype

Manufacturers rely on different technologies to build a prototype required for product development, depending on the required material, type of prototype, complexity, and number of units. Here are the standard processes involved in prototype-making:

CNC Machining

It is a versatile subtractive manufacturing process that uses mills, routers, and lathes controlled by software programs to create prototypes or final products. CNC machining prototypes allow the creation of prototypes with accurate dimensions and a high level of detail using techniques such as milling, turning, grinding, drilling, and more.

Since the CNC machine operates on a computer program, it handles the raw material with high precision. Machined prototypes can undergo different surface finishing treatments to achieve the preferred look and feel. However, CNC prototype machining can cost more than additive processes when handling complex geometries.

3D Printing

3D printing creates prototypes by building one layer over another using digital models. There are different forms of 3D printing, each compatible with specific materials. For instance, SLM and DMLS are 3D printing techniques for metal prototypes, while SLS, FDM, and SLA are ideal for plastic prototypes.

Manufacturers often embrace 3D printing for prototype manufacturing since it is cost-effective, allows rapid production, and can create complex geometries. However, it is particularly suitable for one-off prototypes instead of batches, as printed parts exhibit less material strength than machined ones.

Vacuum Casting

Vacuum casting or urethane casting involves pouring liquid resin into silicone molds under a vacuum to expel air bubbles. It is an efficient process of making prototypes in low volume and an economical alternative to injection molding. Vacuum casting is often used to create concept models because it provides high-quality, detailed parts with a surface finish superior to injection-molded parts.

Sheet Metal Prototyping

This process is best for making different prototypes with metals and short turnarounds. Sheet metal prototyping involves shaping sheet metal into strong, functional prototypes through cutting, bending, welding, and stamping. This process is perfect for working materials like stainless steel, copper, and aluminum. Although sheet metal prototyping is scalable to mass production, its setup costs more than 3D printing methods.

What Types Of Prototypes Can You Make?

There are various kinds of prototypes with distinctive purposes in product development. The type of prototype you choose to develop determines the success of a product, and it accurately represents the final product’s function and appearance, helping your customers grasp the concept and use the product appropriately. We will explore the common types of prototypes you can make in this section:

Concept Prototype

The concept prototype is an early version of your product that focuses on usability and appearance. It indicates the product’s aesthetics, shape, and size. Although not fully functional, it showcases a product’s overall design and functionality. A concept prototype helps product teams understand how the intended customers will interact with the product and identify areas that require refinement before investing further.

Engineering Prototype

This type of prototype is made as a one-off model, representing the final product’s aesthetic and functional aspects as best as possible. Product teams use engineer-approved materials to create engineering prototypes using the same processes as the final product. These prototypes undergo rigorous environmental, thermal, and mechanical testing to evaluate their structural integrity, thermal performance, durability, and stress resistance and optimize their design for manufacturability and production efficiency.

Visual Prototype

A visual prototype showcases the physical attributes of a product without necessarily including its functional components. It doesn’t perform any operational tasks since it only focuses on the design’s aesthetics, form, and size. This prototype is often made using foam or resin. They assess the appearance or ergonomics of product design or display models for marketing and client presentations, gathering early feedback and validation.

Functional Prototype

A functional prototype is built to identify design flaws before investing in mass production. Manufacturers create functional prototypes with typical rapid prototyping processes like 3D printing or CNC machining. Although these prototypes may not closely imitate the final product in appearance, they must work as intended or almost. Product developers use functional prototypes to evaluate the product’s structural integrity and material properties.

Pre-Production Prototype

Pre-production prototypes are built using actual production processes. Hence, they appear and function like the final products. These prototypes test efficiency and scalability and validate the mass production workflow. The main aim of pre-production prototypes is to refine the manufacturing process and identify flaws before full-scale production.

Rapid Prototypes

The product developer makes these prototypes with rapid manufacturing techniques like 3D printing, CNC machining, or laser cutting. Rapid prototypes are used in iterative design processes to speed up product development cycles. The whole process focuses on speed instead of precision or durability because it involves the quick creation of low-cost prototypes for multiple design iterations.

Expert Tips For Creating A Prototype

Prototypes are as important as the finished parts in the product development. Since it is easy to make mistakes when building a prototype, it is essential to follow specific tips to achieve the desired outcomes. Here are some expert tips on prototype making.

Identify the Purpose of Your Prototype

Since prototypes serve different purposes, including assessment of user experience, validating market demand, or testing functionality, manufacturing experts recommend that you clearly define the goals of your prototype at the initial stage. Doing so lets you decide the level of detail and resources you need for your prototype.

Keep it Simple

Complexity can stall the stages of prototyping, increase costs, and make it difficult to identify the flaws of your design. Hence, before adding details, begin with a simple prototype design that allows you to prioritize the essential features that define the product’s functions. Simple prototype design lowers risks, saves time and money, and supports faster iterations in the long run.

Prioritize User Feedback

User feedback is quintessential in every stage of prototype validation. Being a user-centric producer will ensure your product doesn’t fail in the real world since the feedback of your potential users is crucial to improving your prototype. Study how potential users interact with your prototype, identify each design flaw, and make incremental improvements to ensure your design meets users’ needs.

Safeguard Your Design

Once you have developed your prototype and identified its flaws, it is essential to safeguard your intellectual property from plagiarism. Before sharing your ideas with others, it would help to have a non-disclosure agreement (NDA) in place to protect your idea from unauthorized use. Additionally, you can trademark your brand name and logo on your design to prevent competitors from confusing customers with similar branding.

Consider Production Cost

Cost is a critical factor to consider when creating a prototype for your product. As there are different stages involved, from creating a prototype to production, they often have related costs and add up quickly. A great prototype becomes useless if it is too costly to produce at scale.

Therefore, experts advise researching the cost for each activity to prevent investing more money than your budget allows and ensure your final product is affordable and profitable.

Outsource to a Reliable Prototyping Partner

Working with a certified and experienced prototyping partner as a startup or existing company can ensure improved efficiency and product quality. Although you can build some prototypes in-house, partnering with the right CNC machine shop can help streamline your product development cycles and ensure a seamless transition to full-scale production.

More importantly, a reputable prototype manufacturing company like Washxing has access to advanced technology and specialized knowledge in high-precision techniques.

Next Step: Making Your Own Prototypes

Now that you’ve seen how to create a basic prototype, it’s time to start thinking about making your own. The process of creating a prototype is important for any product development project, as it allows you to explore different design options, visualize the end product, and make sure that everything flows together correctly.

Washxing is a rapid prototyping and low-volume manufacturing company focusing on plastic and metal parts, with a one-stop shop from prototype to production. We offer CNC machining, 3D printing, vacuum casting, and rapid tooling services to fulfill your individual product design demands.

Recomendaciones

¿Cómo mecanizar piezas poliédricas de aluminio diseñando rutas de proceso y utillajes?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

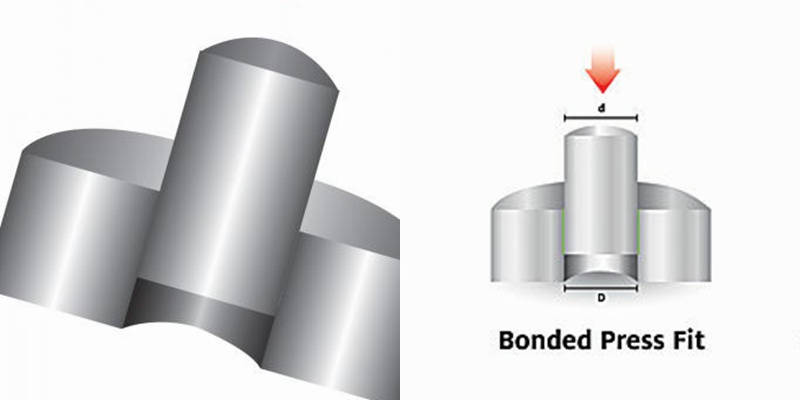

Press Fit Tolerance: Defination, Practices, and Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

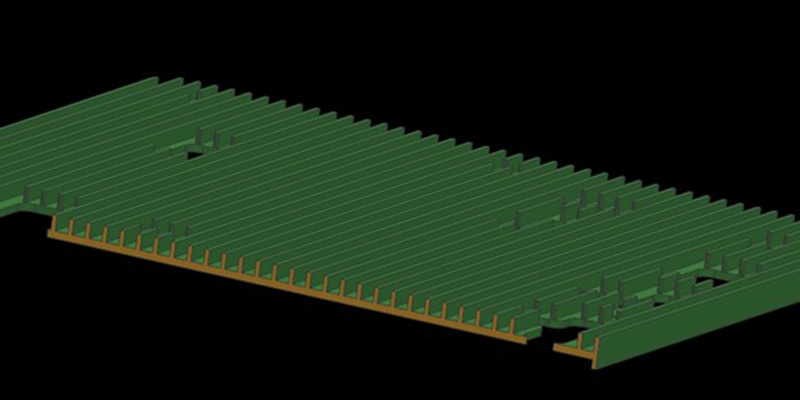

¿Cómo evitar el alabeo y la deformación de piezas grandes y de paredes delgadas durante el mecanizado CNC?

Las piezas de gran tamaño y paredes finas son fáciles de alabear y deformar durante el mecanizado. En este artículo, presentaremos un caso de disipador de calor de piezas grandes y de paredes finas para analizar los problemas en el proceso de mecanizado normal. Además, también ofrecemos una solución optimizada de proceso y utillaje. Manos a la obra El caso se refiere a una pieza en forma de concha fabricada en material AL6061-T6. Estas son sus dimensiones exactas. Dimensiones totales: 455*261.5*12.5mmEspesor de la pared de soporte: 2.5mmEspesor del disipador de calor: 1.5mm...

¿Cómo evitar la colisión de máquinas en el proceso de mecanizado?

Machine collision has always been an inevitable challenge in prototype and part machining. Operator errors, such as failing to perform tool settings, can lead to crashes. It will result in broken tools, scrapped workpieces, and reordering and reprocessing materials. In addition, without the automatic tool setter, manual tool setting when entering Z-value data error can also cause machine collision. In this article, we will share our summarized experiences to help you avoid this issue. Bef...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd