¿Cómo determinar el centro de rotación de rotación al operar una máquina CNC de 4 ejes?

Recomendaciones

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

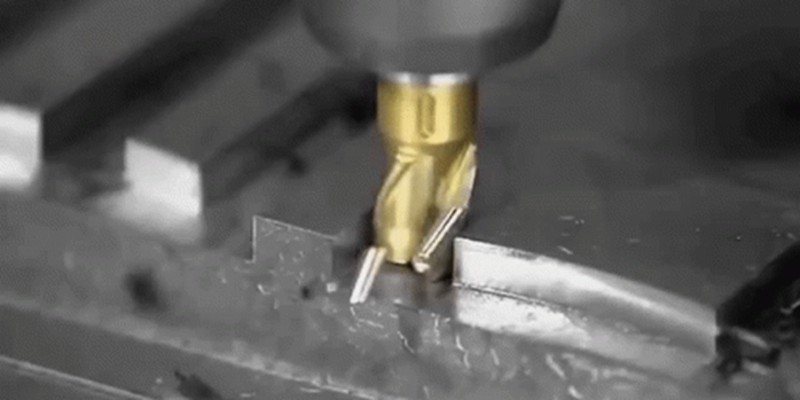

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

Causas y soluciones de las marcas de herramientas en el mecanizado de metales

Las piezas metálicas de precisión suelen fabricarse utilizando diversas tecnologías de mecanizado de precisión, siendo el mecanizado CNC un método habitual. Por lo general, las piezas de precisión suelen exigir altos estándares tanto en dimensiones como en aspecto. Por lo tanto, cuando se utilizan metales de mecanizado CNC como el aluminio y el cobre, la aparición de marcas de herramientas y líneas en la superficie del producto acabado es motivo de preocupación. En este artículo se analizan las razones que provocan marcas y líneas de herramienta durante el mecanizado de productos metálicos....

¿Cómo mecanizar piezas poliédricas de aluminio diseñando rutas de proceso y utillajes?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

Producción y fabricación de puentes: Etapas clave y ventajas

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd