Comment éviter les collisions entre machines dans le processus d'usinage ?

Recommandations

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

Machining Allowance Explained: Its Calculation And Matters

Machining allowance is a fundamental concept in manufacturing. It is a common engineering practice in CNC precision machining, ensuring dimensional accuracy, surface quality, and the production of reliable and functional components for a range of industries, including aerospace, defense, and medical. This article attempts to answer the question: what is machining allowance? We will take a deep dive into the concept of machining allowance and discuss why machinists leave machining allowanc...

Tournage étagé et tournage conique : Quelles sont les différences ?

Le tournage est une opération d'usinage fondamentale qui soutient l'industrie manufacturière depuis des siècles. Il continue d'évoluer et constitue encore aujourd'hui une technique de fabrication essentielle. Cet article aborde deux types d'opérations de tournage : le tournage par étapes et le tournage conique. Nous explorerons le processus de tournage par étapes et le processus de tournage conique et expliquerons leurs différences.Le tournage est essentiellement une opération de coupe au cours de laquelle un outil de coupe affûté façonne une pièce rotative en enlevant de la matière de sa surface....

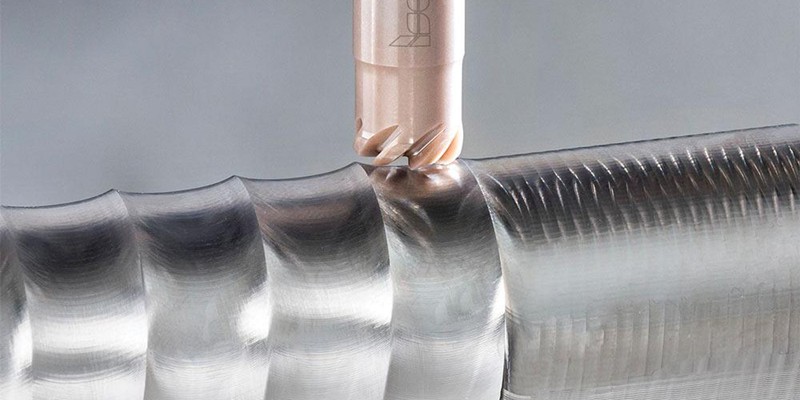

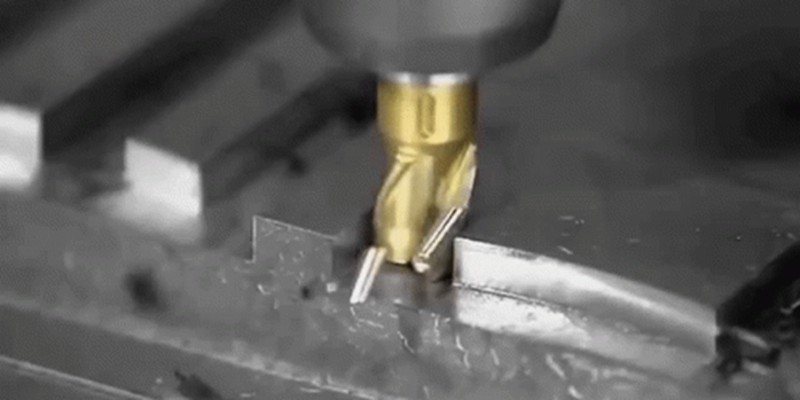

Causes et solutions pour les marques d'outils dans l'usinage des métaux

Les pièces métalliques de précision sont souvent fabriquées à l'aide de diverses technologies d'usinage de précision, l'usinage CNC étant une méthode courante. En général, les pièces de précision exigent des normes élevées en matière de dimensions et d'aspect. Par conséquent, lors de l'usinage CNC de métaux tels que l'aluminium et le cuivre, l'apparition de marques et de lignes d'outils sur la surface du produit fini est un problème. Cet article examine les raisons qui provoquent des marques et des lignes d'outil lors de l'usinage de produits métalliques....

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd