Raccomandazioni

Come lavorare parti poliedriche in alluminio progettando percorsi di processo e attrezzature?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

Produzione e fabbricazione di ponti: Fasi chiave e vantaggi

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

Types Of Milling Explained: Know All Milling Operations

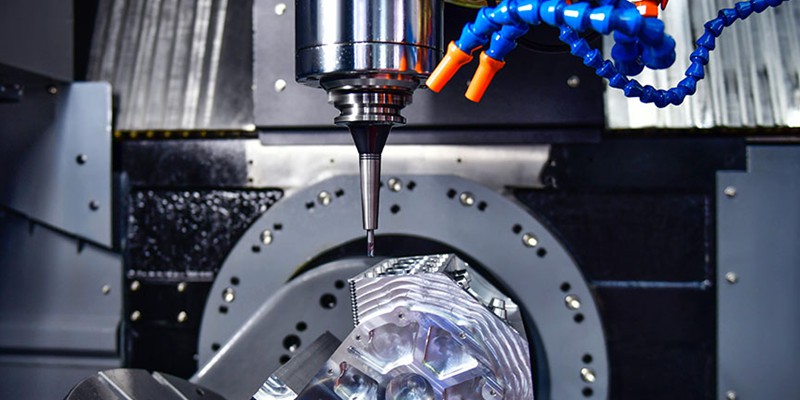

Milling is inarguably the backbone of the manufacturing industry, playing a direct role in high-quality production in industries including aerospace, automotive, medical, and defense. Milling operations are highly versatile and capable of handling complex geometries with precision and speed. In this article, we will discuss the fundamentals of CNC milling and explain various milling operations, helping to choose the right milling type for your applications.Milling is a machining process t...

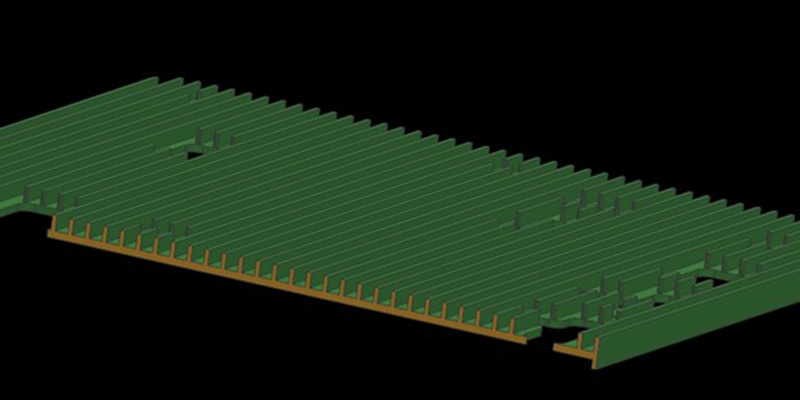

Come prevenire la deformazione e l'incurvamento dei pezzi a conchiglia di grandi dimensioni e a parete sottile durante la lavorazione CNC?

Large, thin-walled shell parts are easy to warp and deform during machining. In this article, we will introduce a heat sink case of large and thin-walled parts to discuss the problems in the regular machining process. In addition, we also provide an optimized process and fixture solution. Let’s get to it! The case is about a shell part made of AL6061-T6 material. Here are its exact dimensions. Overall Dimension: 455*261.5*12.5mmSupport Wall Thickness: 2.5mmHeat Sink Thickness: 1.5mmHe...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd