ブログ

Outdoor cameras are essential for enhancing the security and monitoring of outdoor spaces.

These devices are designed to withstand various weather conditions, ensuring reliable performance in rain, snow, and extreme temperatures.

CNC加工中の大型・薄肉シェル部品の反りや変形を防ぐには?

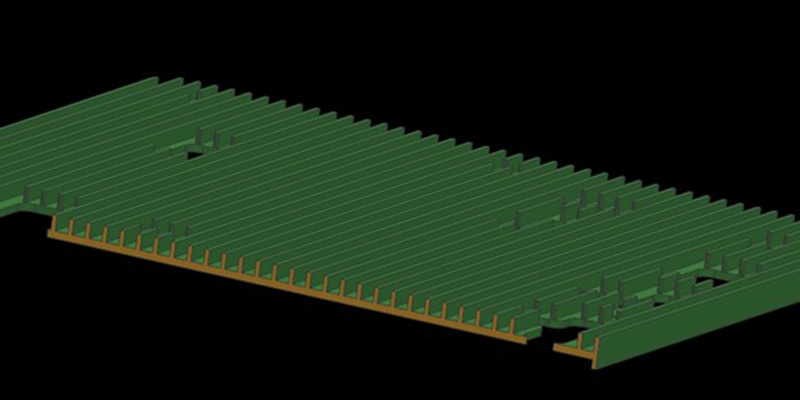

Large, thin-walled shell parts are easy to warp and deform during machining. In this article, we will introduce a heat sink case of large and thin-walled parts to discuss the problems in the regular machining process. In addition, we also provide an optimized process and fixture solution. Let’s get to it! The case is about a shell part made of AL6061-T6 material. Here are its exact dimensions. Overall Dimension: 455*261.5*12.5mmSupport Wall Thickness: 2.5mmHeat Sink Thickness: 1.5mmHe...

4軸CNCマシンの操作時に回転中心を決定するには?

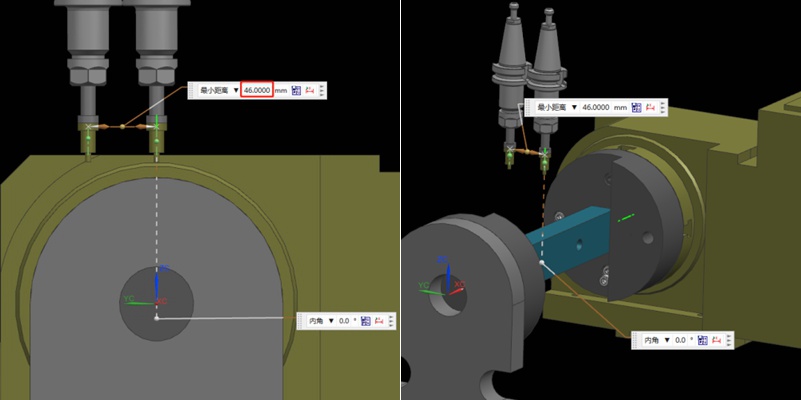

現在、4軸ロータリーテーブルは、機械加工工場では一般的な設備となっている。複数の面の加工を1つの座標で完了させるためには、プログラミング座標と回転テーブルの座標を同期させる必要がある。この記事では、4軸ロータリーテーブルの回転中心を決定する方法を紹介します。ここでは、工作機械のX軸を中心に回転する4軸ロータリーテーブルを示し、回転軸をA軸と呼びます。一言で言えば...

金属加工におけるツールマークの原因と解決策

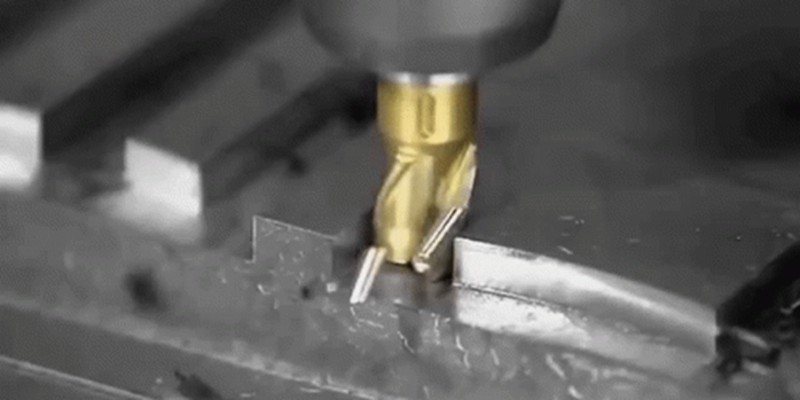

Precision metal parts are often manufactured using various precision machining technologies, with CNC machining being a common method. Usually, precision parts typically demand high standards for both dimensions and appearance. Therefore, when using CNC machining metals such as aluminum and copper, the occurrence of tool marks and lines on the finished product’s surface is a concern. This article discusses the reasons that cause tool marks and lines during the machining of metal products....

加工工程での機械衝突を避けるには?

Machine collision has always been an inevitable challenge in prototype and part machining. Operator errors, such as failing to perform tool settings, can lead to crashes. It will result in broken tools, scrapped workpieces, and reordering and reprocessing materials. In addition, without the automatic tool setter, manual tool setting when entering Z-value data error can also cause machine collision. In this article, we will share our summarized experiences to help you avoid this issue. Bef...

加工ルートと治具の設計による多面体アルミ部品の加工方法とは?

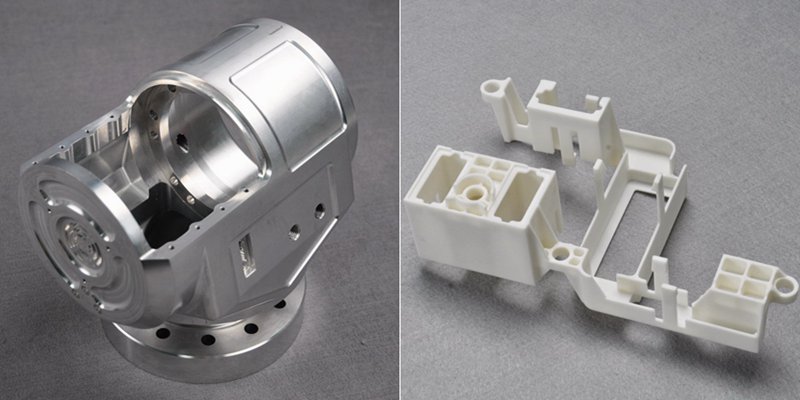

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

製造のためのCNC加工設計:エキスパートテクニカルガイド

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!The depth of cavities and grooves is typically limited by the cutting tool diameter us...

ブリッジの生産と製造:主な段階と利点

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

ステップターニングとテーパーターニング:その違いは?

Turning is a fundamental machining operation that has supported the manufacturing industry for centuries. It continues to evolve and is a core manufacturing technique to this day. This article will discuss two types of turning operations: step turning vs taper turning. We will explore the step process and taper turning process and explain their differences.Turning is essentially a cutting operation where a sharp cutting tool shapes a rotating workpiece by removing material from its surfa...

深セン洗星科技有限公司

深セン洗星科技有限公司