권장 사항

Cost Of CNC Machining: What Affects & How to Save It?

CNC machining is a technique used to make precision parts and replicate amazing designs. There are a lot of advantages of CNC machining, such as increasing the speed of parts production. It also reduces human errors during manufacturing as it is being controlled by the computer. However, many people do not seem to understand the rationale behind its cost. The machine and material you use can affect the price. Today, many customers still struggle with CNC machining cost calculation. With t...

Press Fit Tolerance: Defination, Practices, And Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

가공 공정에서 기계 충돌을 피하는 방법은?

기계 충돌은 프로토타입 및 부품 가공에서 항상 피할 수 없는 과제였습니다. 공구 설정 실패와 같은 작업자 오류는 충돌로 이어질 수 있습니다. 이는 공구 파손, 공작물 폐기, 재료 재주문 및 재가공으로 이어질 수 있습니다. 또한 자동 공구 세터가 없는 경우 Z값 데이터 오류 입력 시 수동 공구 설정도 기계 충돌을 일으킬 수 있습니다. 이 기사에서는 이러한 문제를 방지하는 데 도움이 되는 요약된 경험을 공유합니다. Bef...

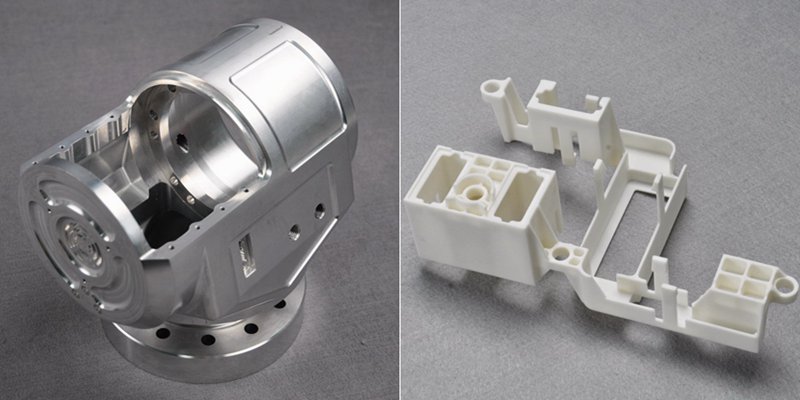

제조용 CNC 가공 설계: 전문가 기술 가이드

효율적인 CNC 설계는 기능, 비용, 생산 효율성의 균형을 맞추는 데 핵심입니다. 이 가이드라인을 따르면 일반적인 설계 문제를 방지하고 제조 가능성을 개선하며 생산 프로세스를 간소화할 수 있습니다. 얇은 벽과 깊은 캐비티 최소화부터 합리적인 공차 설정까지, 이 솔루션의 각 권장 사항은 가공을 간소화하는 동시에 품질을 보장하는 데 도움이 됩니다. 시작하겠습니다! 캐비티와 홈의 깊이는 일반적으로 절삭 공구 직경에 의해 제한됩니다...

심천 워싱 기술 유한공사

심천 워싱 기술 유한공사