Hoe vervorming en kromtrekken in grote en dunwandige onderdelen te voorkomen tijdens CNC-bewerking?

Aanbevelingen

How To Create A Prototype With Steps: An Expert Guide

A prototype is an early version or physical model of a product idea that manufacturers can test and refine before investing in mass production. It acts as a product template and provides a practical approach to understanding a product’s appearance and function before production. When developing a product, product teams create a product prototype to test the product’s usability, design, and performance, gather user feedback, identify potential issues in the early stages, and identify possib...

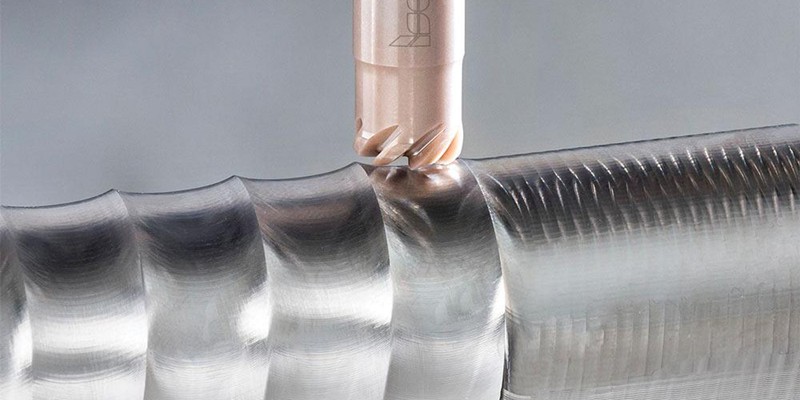

Machining Allowance Explained: Its Calculation And Matters

Machining allowance is a fundamental concept in manufacturing. It is a common engineering practice in CNC precision machining, ensuring dimensional accuracy, surface quality, and the production of reliable and functional components for a range of industries, including aerospace, defense, and medical. This article attempts to answer the question: what is machining allowance? We will take a deep dive into the concept of machining allowance and discuss why machinists leave machining allowanc...

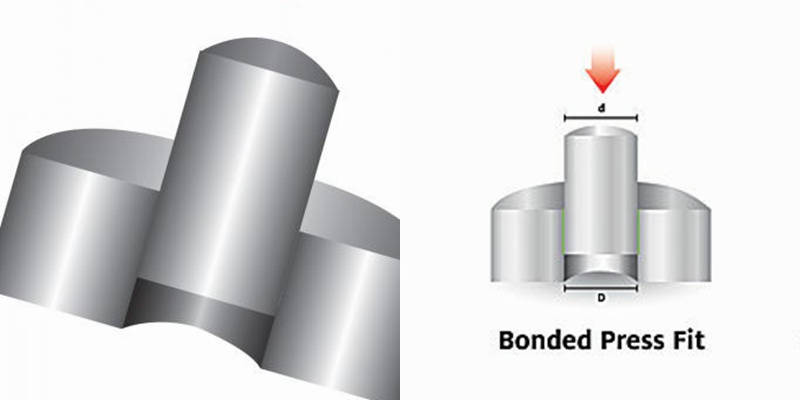

Press Fit Tolerance: Defination, Practices, and Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

All You Need To Know Engineering Drawing And Its Elements

Drawing or painting a picture is a great technique to convey one’s thoughts. Within the broad concept of industrial design, engineering drawing or technical drawing is an essential skill for designers working with the production of real objects. Therefore, engineering drawing is arguably one of the fundamentals of engineering design that serves several critical purposes. It is a standard technical drawing carrying essential design information, a mode of communication between different eng...

ShenZhen Washxing Technology Co, Ltd

ShenZhen Washxing Technology Co, Ltd