Projektowanie obróbki CNC dla produkcji: Przewodnik techniczny eksperta

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!

1. Avoid Deep Cavities and Grooves

The depth of cavities and grooves is typically limited by the cutting tool diameter used to machine internal corners. A good rule of thumb is to keep cavity depth within 3-4 times the tool diameter or groove depth less than 4 times the feature width.

2. Design Larger Internal Corner Radii

In CNC machining, all internal cuts create rounded corners with a radius equal to half the tool diameter. However, using smaller tools increases machining time. For efficiency, we recommend the corner radius should be greater than one-third of the machining depth. Ideally, design the largest possible internal corner radii and maintain a uniform radius for all internal edges to use the same cutting tool for machining.

If large radii cannot be used due to design requirements (e.g., to fit with a square component), consider the following alternatives to avoid smaller internal corner radii.

3. Avoid Thin Walls

The features of thin walls are prone to vibration during machining, especially in taller features. For metal parts, the minimum wall thickness is recommended to be 0.5-0.8 mm, while for plastic parts, it should be 1.0-1.5 mm. If walls are structural or involve tall features, increase thickness accordingly. For thin-walled designs that must be required, combining CNC machining with sheet metal riveting is a cost-effective solution.

Additionally, for sheet parts with a thickness of 6 mm or less, we recommend to be designed for standard sheet thicknesses for procurement.

4. Avoid Deep Holes

For both blind and through holes, the depth should not exceed four times the diameter of holes, the minimum hole diameter is 1 mm, and standard-sized holes are preferable. Standard drill bits are efficient and precise, whereas non-standard holes require end mills, increasing costs. For blind holes, note that drill bits create a 135° tapered angle at the bottom, whereas machined by an end mill is flat.

5. Use Standard Threads

When designing threads, prioritize standard sizes, the larger threads, the easier it is to process. Thread length should not exceed three times the hole diameter. For blind hole threading, leave at least half the hole diameter as the extra depth at the bottom.

For large-diameter threaded holes or studs, allow for a hole recess at the bottom of the threads to ensure that the threads can be fully tightened. Consider also using inserts such as threaded coils or copper nuts, which are more durable than bare threads, especially in materials such as aluminum or plastic, and are easy to install.

6. Minimize the Number of Clamping

To ensure machining accuracy, minimize the number of times the part is clamped. Ideally, all machining should be completed in a single setup. If the part’s structure requires machining from different orientations, multiple setups or multi-axis CNC machines may be necessary, increasing costs. For example, the left design below requires two clampings, while the right design can be completed in one.

7. Avoid Non-Functional Aesthetic Features

Non-functional aesthetic features, such as polishing, anodizing, painting, or plating, add post-processing costs. Unless necessary, avoid these designs to reduce machining time and expenses.

8. Avoid Designing Small Features

Most CNC machines have a minimum tool diameter of 2.5 mm. The smaller the diameter of the tool, the more likely it is to break, requiring slower feed rates and increased machining time. Unless required, avoid small features. At Washxing, our CNC machines can use tools with diameters as small as 0.3 mm, achieving fine corner radii as small as 0.15 mm.

9. Avoid Unmachinable Features

Not all design features are feasible for CNC machining. For example, closed-end holes and U-shaped holes cannot be directly machined. Holes that are closed at both ends need to be processed as blind holes first, and then a threaded assembly in the top area of the hole to make the hole closed. In addition, U-shaped holes need to be processed by splitting parts.

10. Avoid Small or Raised Text

For marking part numbers or logos, avoid complex text designs. Laser engraving or etching is often a better option. If milling text is necessary, choose recessed instead of raised fonts, with a depth no greater than 0.3 mm and appropriately sized lettering.

11. Consider Undercuts

Undercut designs, such as T-slots and dovetail grooves, require specialized T-slot cutters. Standard dovetail angles are 45° or 60°. Ensure the T-slot width at the top is larger than the cutter diameter, typically four times the engagement depth. If the undercut is part of a through feature, side machining is possible. For circular dovetails with seals, include an entry point with a diameter matching the dovetail’s maximum width.

12. Avoid External R Angle on Part Edges

To prevent parts from being scratched during handling or assembly, consider chamfers or external radii. External radii require ball-end mills or custom tools for multiple passes, while a 45° chamfer can be completed in one pass using a chamfer tool. For efficiency, prioritize 45° chamfers on part edges.

13. Set Tolerances Reasonably

For metal parts, unspecified dimensional tolerances typically meet ISO 2768-fH standards, while plastic parts conform to ISO 2768-mK. Overly tight tolerances increase machining difficulty and time. Only specify tight tolerances when necessary. For assembly fits, metal parts can typically achieve IT7 grade tolerances, such as H7 for holes and h7 for shafts. The smaller the tolerance grade, the greater the machining difficulty.

By applying these CNC machining design tips, you can enhance manufacturability, reduce costs, and improve efficiency. At Washxing, our advanced CNC machining capabilities and expert team are ready to bring your designs to life with precision and quality. Whether you need prototypes or end-use parts, contact us today to get a free DFM for your projects!

Recommendations

Jak obrabiać wielościenne części aluminiowe poprzez projektowanie tras procesu i osprzętu?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

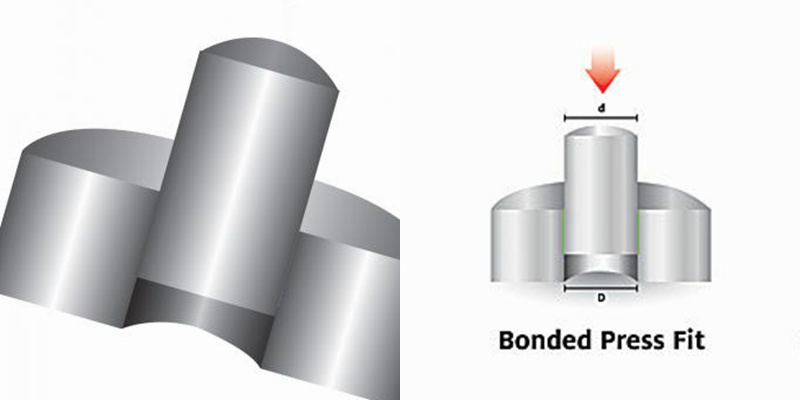

Press Fit Tolerance: Defination, Practices, And Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

Types Of Milling Explained: Know All Milling Operations

Milling is inarguably the backbone of the manufacturing industry, playing a direct role in high-quality production in industries including aerospace, automotive, medical, and defense. Milling operations are highly versatile and capable of handling complex geometries with precision and speed. In this article, we will discuss the fundamentals of CNC milling and explain various milling operations, helping to choose the right milling type for your applications.Milling is a machining process t...

ShenZhen Washxing Technology Co, Ltd

ShenZhen Washxing Technology Co, Ltd