Как обрабатывать многогранные алюминиевые детали, разрабатывая технологические маршруты и приспособления?

Рекомендации

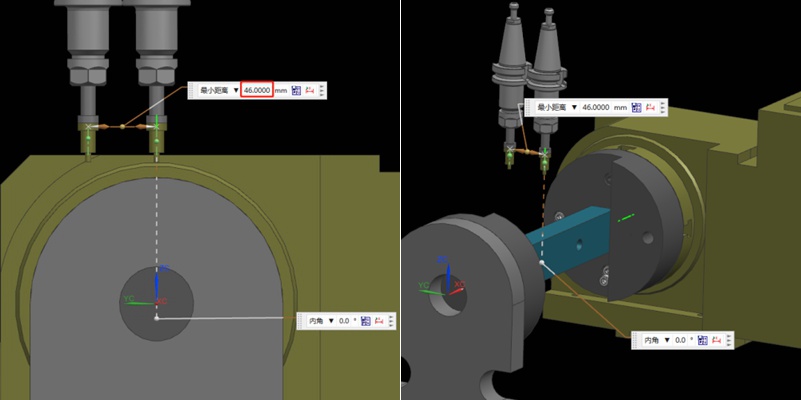

Как определить центр вращения при работе на 4-осевом станке с ЧПУ?

В настоящее время четырехкоординатный поворотный стол является обычным оборудованием в механическом цехе. Для того чтобы выполнить обработку нескольких граней в одной координате, координаты программирования должны быть синхронизированы с координатами поворотного стола. В этой статье мы расскажем о методе определения центра вращения 4-осевого поворотного стола. Здесь показан 4-осевой поворотный стол, который вращается вокруг оси X станка, где ось вращения называется осью A. Одним словом,...

Cost Of CNC Machining: What Affects & How to Save It?

CNC machining is a technique used to make precision parts and replicate amazing designs. There are a lot of advantages of CNC machining, such as increasing the speed of parts production. It also reduces human errors during manufacturing as it is being controlled by the computer. However, many people do not seem to understand the rationale behind its cost. The machine and material you use can affect the price. Today, many customers still struggle with CNC machining cost calculation. With t...

Ступенчатое точение против конического точения: В чем разница?

Токарная обработка - это фундаментальная операция, которая веками поддерживала производственную индустрию. Она продолжает развиваться и является основной технологией производства по сей день. В этой статье мы рассмотрим два типа токарных операций: ступенчатое и коническое точение. Мы рассмотрим процесс ступенчатого и конического точения и объясним их различия.Токарная обработка - это, по сути, операция резания, при которой острый режущий инструмент придает форму вращающейся заготовке, удаляя материал с ее поверхности...

Как избежать столкновения станков в процессе обработки?

Столкновение станков всегда было неизбежной проблемой при обработке прототипов и деталей. Ошибки оператора, например, невыполнение настроек инструмента, могут привести к столкновениям. Это приведет к поломке инструментов, браку заготовок, повторному заказу и повторной обработке материалов. Кроме того, при отсутствии автоматического устройства настройки инструмента ручная настройка инструмента при ошибке ввода данных Z-значения также может привести к столкновению станков. В этой статье мы поделимся нашим обобщенным опытом, чтобы помочь вам избежать этой проблемы. До...

Шэньчжэнь Washxing Technology Co.

Шэньчжэнь Washxing Technology Co.