All You Need To Know Engineering Drawing And Its Elements

Drawing or painting a picture is a great technique to convey one’s thoughts. Within the broad concept of industrial design, engineering drawing or technical drawing is an essential skill for designers working with the production of real objects. Therefore, engineering drawing is arguably one of the fundamentals of engineering design that serves several critical purposes. It is a standard technical drawing carrying essential design information, a mode of communication between different engineering departments, and even a legal document. This article takes a deep insight into the topic of engineering drawing. We will discuss its role in mechanical design, types, key elements, and various engineering drawing examples. Engineering drawings, also known as mechanical drawings, manufacturing blueprints, drawings, etc., are technical drawings that show the shape, structure, dimensions, tolerances, accuracy, and other requirements of a part in the form of a plan. It helps to define the requirements of an engineering part and conveys the design concept. Engineers use engineering drawings to convey information about a particular object. The term “detail drawing” refers to a drawing that is commonly used to specify the geometry required for the building of a component. Even the most basic components require a lot of drawings to fully describe them. An engineering drawing can be used as a starting point for the creation of more comprehensive manufacturing drawings, manufacturing blueprints, mechanical drawings, dimensional prints, and more. Detailed information about the drawing, such as who drew it and who approved it, is contained in a title block or information box. An engineering drawing serves several core purposes in a professional engineering environment. Let us take a look at these in detail. The primary purpose of a mechanical drawing is the communication of design intent. An engineering drawing is the technical equivalent of a painting – a mode of expression for the artist. It is important to understand that ‘design intent’ is not limited to basic information about dimensions, geometry, and materials. Rather, its scope is much more expansive than the basics of mechanical design. Engineering diagrams also communicate practical information like engineering tolerances fit and surface finish. Moreover, when engineering diagrams properly convey design intent through appropriate engineering drawing symbols, they act as guidelines for the production team regarding what goals to set, manufacturing processes to use, and parameters to select. A technical drawing is the most useful information manufacturing departments get from designers. It helps the manufacturer understand what the designer intends and wants them to do. It provides clear instructions on how to produce the part, with key requirements like dimensional tolerances, form tolerances, and desired surface finish. As the discussion above highlights, this information is crucial to choosing the best manufacturing techniques and parameters. In fact, the mechanical drawing is such a standard form document that discussions between the design and manufacturing teams on issues like manufacturability oftentimes take place directly on the drawing itself. It serves as the perfect discussion board to understand requirements, deal with miscommunications, and mull over ideas. Quality control is another department that benefits from engineering drawings. Once the manufacturing team finishes its job, the components along with their engineering drawing reach the quality control office. As before, the technical drawing conveys all the quality requirements necessary for the quality team to perform their job. These instructions may include information on specific mechanical testing techniques or tolerances/allowances. The quality report, which passes or rejects a part, always references the corresponding technical drawing, underscoring its significance in quality control. An engineering drawing also serves as a legal document in many cases. Oftentimes, they carry sensitive information regarding proprietary engineering designs that solely belong to a specific person or organization. In fact, they are an important component of patent applications, where the visual representation of the invention helps draft definitions and claims. There are two common methods of engineering drawing: manual drawing and computer drawing. Drawing boards, paper, rulers, calipers, and round gauges are essential tools for manual drawing. Suitable for university courses, they play an important role in developing the spatial imagination and conceptual skills that underpin creative thinking in university students. Computer drawing, commonly used in CAD software, is more suitable for the contemporary manufacturing industry. CNC machining centers equipped with CNC systems can read data and information directly from digital files and generate machining programs accordingly, saving time and effort. At the same time, computerized drawing facilitates the modification of drawings, on the one hand allowing different versions of the design to be retained, and on the other hand eliminating the tedious process of manual drawing. The 3D model can also be used in machining centers but requires engineering drawings to communicate important information such as materials, tolerances, special requirements, etc. We usually recommend the use of a 3D model in conjunction with engineering drawings. Engineering drawings are detailed documents with numerous key elements. These elements carry necessary information that contributes to the completeness and comprehensibility of the mechanical drawing. With each part of the engineering drawing having a well-defined purpose, it is good to know what it is to be able to create and read professional drawings. The first and foremost element in a technical drawing is the geometry of the part. The discussion above describes in detail how design engineers include geometry in engineering drawings through different types of views. The bulk of the drawing body is composed of engineering diagrams, and depending upon the complexity of the part, there can be multiple views of different types spanning several pages. One may gauge the importance of this element by the fact that all the drawing views in the previous section relate to part geometry one way or another. An engineering drawing doesn’t have equal lines. A part’s visible and concealed boundaries, centerlines, and other details can all be displayed using the various choices. The following are the types of lines. A drawing line, or a continuous line, is the most common. It’s a visual representation of an object’s physical boundaries. To put it another way, a continuous line is used to draw the real objects. Variations in line thickness are used; thicker lines are used on the outside contour and thinner lines are used on the inner contour. Lines that are not visible to the naked eye can reveal information that would otherwise be obscured by the designs. The length of an interior step in a turned part can be shown using hidden lines instead of a section or cutout view. Parts with holes and symmetrical features can be shown by using center lines. Symmetry can reduce the number of dimensions in a drawing and make it more visually appealing, making it easier for the reader to comprehend. Extension lines are used to describe the data being collected. Two arrowheads separate the extension lines on the dimension line from the measurement above (or inside, as shown in the image above). When a view is broken, break lines appear. In the case of a part that is 3000 mm long and 10 mm wide and has the same geometric qualities, a break-out provides all the information without taking up too much space. CNC machines necessitate complete views of the workpieces in order to cut them. Alternatively, the manufacturing engineer will have to re-create the entire part from the measurements alone. The cutting plane lines illustrate the path of the cutout in a cutout view. The A-A cutting line may be seen here bringing both types of holes into view. Besides geometry and lines, dimensions and tolerances are another important element of engineering drawing assembly. They provide exact information about the size and form of the design, putting the scope of the project into perspective for teams down the line. Typically, dimensions and tolerances appear side by side as the tolerance applies to the dimensions themselves. For example, a typical dimension may appear as in the example below. It communicates that the nominal dimension is 20.00 and that its allowable deviation (tolerance) can be +0.05 in the positive direction and 0.00 in the negative direction. Designs very frequently use engineering drawing symbols in technical drawings to indicate various things. While geometry and dimensions are necessary to communicate the design, there is still a great deal of information that cannot be expressed through them. For these, engineers use symbols. A common use of symbols is in Geometric Dimensioning & Tolerancing (GD&T), which primarily focuses on defining and tolerancing the form and size of drawing features. For example, there are symbols for entities such as cylindricity and parallelism, both of which are difficult to convey through lines or dimensions. Another common use is on welding joints. There are numerous types of welding joints with various specifications. Rather than writing a note for each joint, engineers use symbols for convenience. The title block is an essential part of any engineering drawing. Typically, it is a small table at the bottom right corner of the drawing, and it carries critical information regarding the identity and origin of the document. Some of the main elements are: The key elements of engineering drawing in the previous sections appear in every drawing. In addition to these, organizations may choose to add more information due to technical needs or convenience. A few examples of additional information may include: In large or complicated technical drawings, coordinates are commonly employed and positioned along the drawing’s boundaries. When discussing the drawing’s content, these points of reference serve as a guide. Now, let’s dig a bit deeper into what goes inside the drawing space of a technical drawing. Engineers communicate their design specifications through numerous types of engineering drawing views. Each view provides a different perspective, adding clarity and detail to the drawing. The main types of views in engineering diagrams are as follows: The orthographic view is the core of an engineering drawing’s content. A 2D representation of a three-dimensional object is called an orthographic view or orthographic projection. Thus, a 2D view must provide all the information necessary for the production of a part. Any length distortion is avoided with this representation. As the most common method for conveying all the necessary information, multiview drawings often include three views: It’s conceivable that a few extra views are required to display all of the information. Less is definitely more. Regionally, the views are a little different. Compare the US and ISO layouts by taking a look at this image. Drawing layouts in ISO and the United States are in direct opposition to one another. The one on the left is known as a first-angle projection. There is a top view, a front view, a side view, and so on in this arrangement. In Europe, the ISO standard is most commonly used. A third-angle projection may be seen to the right of the image. All of these images are arranged in chronological order. The United States and Canada are particularly fond of this arrangement. The figure above is an example of an isometric view. Isometric drawings depict three-dimensional objects. When compared to the front view, all vertical lines remain vertical, and parallel lines are depicted at a 30-degree angle. Vertical and parallel lines have the correct length. Using a ruler and the scaling of the picture, for example, you can simply measure the length of a paper drawing. Angled lines are not the same. It’s critical to know the difference between an isometric view and a perspective view. In art, perspective views depict an object as it appears to the human eye. Engineers do not rely on optical illusions but rather stick to the facts. A partial view is a view obtained by projecting a part of an object onto the basic projection plane. Use arrows with letters to indicate the part to be expressed and the direction of projection, and indicate the name of the view. The local view can be configured in the form of the basic view or configured and marked in the form of the configuration towards the view. As a callout or segment in other views, a detailed view shows the model in its entirety. The detail view often depicts the model at a much finer level of detail than the parent view does. An auxiliary view is an orthographic view for non-horizontal or non-vertical planes. It aids in the presentation of inclined surfaces without distortion. An oblique view is a view of an object projected into a plane not parallel to the basic projection plane. The oblique view is usually configured in the form of a view towards, with an arrow with a capital letter indicating the direction of projection, and the same letter marked above the corresponding oblique view. If necessary, a rotated configuration of the oblique view is allowed. The capital letter indicating the name of this view should be near the arrow end of the rotation symbol, and it is also permitted to mark the rotation angle after the letter. In actual production, the shape of the part is very varied, only the above views are not enough to express the internal and external shape and structure of the part clearly, for this reason, there are a variety of ways to express the shape of the structure of the part: sectional view, cross-sectional views, partial enlargement view, etc. You can better depict the interior of a complicated object, such as an automobile’s engine block, by sketching the object as it would appear if cut apart. In this manner, the sketch’s many hidden lines are erased. Sectioning is the practice of drawing an object’s interior structure by illustrating it as if it had been cut apart. Sectioning is a common feature of many industrial designs. Sectioning the block above results in blocks A and B, as shown. An object in a painting or sketch can be sectioned in any way you like, just like an apple. This type of section is called a full section when a cutting plane line passes completely through an object. Sectioning an object can be done whenever a closer look is necessary. This object has been cut into two halves, as you can see. When the part has a symmetrical plane, the graph projected on the projection plane perpendicular to the symmetrical plane can be bounded by the symmetrical centerline, half of which is drawn as a sectional view and the other half as a view. This sectional view is called a semi-sectional view. The semi-sectional view is used for symmetrical members whose internal and external structures need to be expressed. The dividing line of the semi-sectional view is drawn with a single dotted line. Due to the symmetry of the graph, the internal structure of the parts has been clearly expressed in the section, and no hidden lines are drawn in the view part. Views with broken-out sections can be used to reveal the model’s inner details by cutting away material at a predetermined depth. The broken-out part is defined by a closed profile, typically a spline. Users can enter a precise depth or reference a place in another view to specify a depth. With respect to an object’s cross-sectional area, the orthographic projection of that object’s cross-section is equal to its overall area. A cylinder of height h and radius r, for example, has when seen in an orthogonal direction and along its central axis. The use of partial views in technical drawing documentation makes it easier to provide the needed details on parts. A lot of the time, it’s easier to show more detail about a part when you use partial views of the part. Engineers often make the mistake of trying to incorporate all the information about each individual part in an assembly drawing. This can be avoided if you keep in mind that the goal of these technical drawings is to facilitate the assembly process. In order to accomplish this, you can utilize tools like section views, numbered pieces, general dimensions, cuts, and detail views (or close-ups). Regardless of the method of attachment, it should be apparent where each component goes and how it is attached. For your benefit, make sure the bill of materials has accurate information about part numbers, names, and quantities. All of this will help you design assembly drawings that will make your projects in the machine shop more efficient. Engineering drawing is a highly standardized field with numerous international standards in place to guide professionals across the globe. These standards apply to various aspects of technical drawings from the basics of engineering diagrams to engineering drawing symbols. The ASME Y14.5, Y14.3, and Y14.100 are arguably the most widely accepted standards defining good practices for geometric dimensioning and tolerancing (GD&T), projection views, and standardized frameworks for engineering drawings, respectively. Furthermore, the ISO 128 and ISO 129 standards cover critical information regarding line types, scales, projections, and tolerancing rules. Engineering design is a wide discipline, and it covers other areas apart from mechanical drawing, which is reflected in the fact that there are numerous kinds of engineering diagrams. This section gives an overview of some of these main types. 1. Dimensions marked incomplete, messy, omission, and repeated marking. 2. View errors. Views are incorrectly placed or do not correspond to each other and do not clearly express the design intent. 3. Workpiece dimensional accuracy requirements are high but not marked dimensional tolerance, resulting in large machining errors and scrap workpieces. 4. The technical requirements of the parts (including dimensional tolerances, form tolerances, and surface roughness) are not marked standardization.What Is Engineering Drawing?

Practical Roles Of Engineering Drawings

Communication of Design Intent

Determine Manufacturing Process

Quality Control

Legal Document

How To Prepare An Engineeringl Drawing?

Key Elements Of An Engineering Drawing

1. Geometry

2. Line Types

2.1 Continuous Lines

2.2 Hidden Lines

2.3 Center Lines

2.4 Dimension Lines

2.5 Broken View Lines

2.6 Cutting Plane Lines

3. Dimensions/Tolerances

4. Symbols

5. Title Block

6. Additional Information

7. Coordinates

Types Of Engineering Drawing Views

1. Orthographic View

2. Isometric View

3. Partial View

4. Detail View

5. Auxiliary View

6. Oblique View

7. Sectional View

7.1 Full Sectioning

7.2 Semi-sectional View

7.3 Broken-out Sections

8. Cross-sectional View

9. Partial enlargement View

10. Assembly Drawings

Common Standards For Engineering Drawings

Other Engineering Drawings

4 Common Mistakes In Engineering Drawing

建議

Press Fit Tolerance: Defination, Practices, And Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

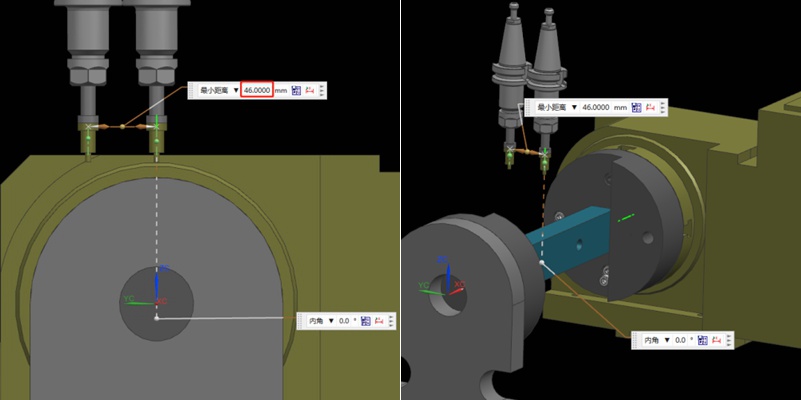

操作 4 軸 CNC 機床時,如何確定旋轉軸的旋轉中心?

現今,四軸旋轉工作台已是加工車間常見的設備。為了在一個座標完成多個面的加工,編程座標必須與旋轉工作台的座標同步。在這篇文章中,我們將與大家分享一個確定四軸旋轉工作台旋轉中心的方法。在這裡,我們展示了一個繞著工具機 X 軸旋轉的四軸旋轉工作台,其中旋轉軸被稱為 A 軸。總而言之,...

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

銑削種類說明:瞭解所有銑削作業

毫無疑問,銑削加工是製造業的骨幹,在航空航天、汽車、醫療和國防等行業的高品質生產中發揮著直接作用。銑削作業具有高度的通用性,能夠精準快速地處理複雜的幾何形狀。在這篇文章中,我們將討論 CNC 銑削的基本原理,並解釋各種銑削操作,以協助您選擇適合應用的銑削類型。

深圳市洗星科技有限公司

深圳市洗星科技有限公司