橋樑生產與製造:關鍵階段與效益

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach.

Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article offers insights into bridge production and its key technologies.

What is Bridge Production?

The concept of bridge production is the intermediate production process between the development of the prototype and manufacturing on a large scale. Some processes involved in this concept include additive production, the use of short-run production tools, and rapid prototyping. These are employed to produce the objects in small batches to help save the cost of mistakes.

Bridge manufacturing helps prevent the launch of products with poor design into the market. It also aids in evaluating customer acceptance and reviewing a particular product without investing the huge capital needed for full-scale production. The method is like a quick check for product performance and customer review by the producers before large-scale production.

Key Phases of Bridge Production

The concept of bridge production requires a seamless combination of different stages to optimize the entire process. These phases are necessary to enable the smooth transition from design to bridge production to mass or large-scale production.

Initial Short-Run Production

The main objective of the initial short-run production is to validate product design and the ability to produce without spending the same amount of resources used in large-scale production. The major technologies used for this stage of bridge production to produce smaller quantities are additive manufacturing and CNC machining.

The required or standard number for an initial stage short-run production is about a few dozen or hundreds. The most important thing is getting a statistically proven market using the most cost-effective means possible.

Market Testing and Presale Strategies

The market assessment is a very essential metric used in bridge production. Before a product is produced on a large scale, manufacturers can gauge market reaction by interviewing potential consumers and gathering their opinions. It makes it easier to gather important information about customer preferences, usability, and functionality—information that is essential for making well-informed changes to product design.

Implementation of Design Changes

Implementing design improvements requires the input gathered during the market testing phase. The main goal of this bridge production stage is to incorporate the knowledge gathered from market research to refine and enhance the product design. To improve the product’s use and appeal, optimization may involve ergonomic adjustments, functional upgrades, or aesthetic changes. By ensuring that the finished product surpasses the client’s expectations, this iterative phase reduces the likelihood of a market failure.

Benefits of the Bridge Production Process

Scaling manufacturing processes to efficiently satisfy market needs, lower production costs, and preserve quality is why manufacturers adopt bridge manufacturing.

Risk Reduction and Design Validation

Bridge production allows companies to thoroughly test and validate their designs before committing to mass production. By creating prototypes or low-volume production parts, businesses can identify potential flaws in design, functionality, or manufacturing processes. This minimizes the risk of costly errors during large-scale manufacturing and ensures that the final product meets quality standards and market expectations.

Cost Efficiency and Resource Allocation

Investing in bridge production helps optimize resources by addressing issues early in the product lifecycle, reducing wastage and rework costs. It eliminates the need for expensive tooling adjustments later in mass production. Companies can also allocate saved funds toward marketing, distribution, or other key aspects of a successful product launch.

Supply Chain Flexibility and Rapid Response

In scenarios where demand surges unexpectedly or supply chains face disruptions, bridge production offers a reliable solution. By leveraging techniques like 3D printing, CNC machining, or bridge tooling, businesses can quickly produce critical components or parts. This ensures a smooth supply chain and prevents delays, maintaining customer satisfaction and market competitiveness.

Main Technologies in Bridge Tooling Production

The idea of bridge production works on the use of certain technologies that make production possible. These technologies help to optimize efficiency and cost-effectiveness as well as ensure scalability in the use of bridge production. Here are the main technologies involved in bridge production

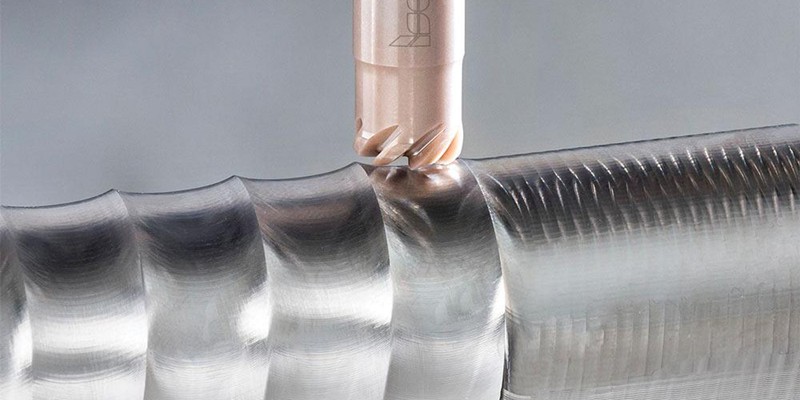

CNC Machining

CNC (Computer Numerical Control) Machining enables the accurate subtraction of solid material layers to achieve a desired shape or form for a part or whole object. It also allows the user to add the desired features after removing parts of the solid material. It employs the use of an automatic machine or tool to get the precise shape through high-precision cuts on the material.

The essence of CNC machining in bridge production is mostly due to its ability to deliver accuracy and precision at all times. These are needed in the bridge production stages so as to avoid excessive loss and waste of production materials.

Injection Molding

The concept of injection molding involves injecting molten material into a mold of a specific shape and letting it cool down to produce certain items. Injection molding is a vital process in bridge production, offering a cost-effective and efficient method for creating high-quality low-volume parts before mass production.

This technique enables companies to produce components from production-grade materials, ensuring accurate testing of functionality, performance, and durability. By using injection molding, businesses can identify design flaws early and make necessary adjustments, reducing risks during mass production.

3D Printing

3D printing plays an important role in bridge production by offering flexibility and speed in creating prototypes and low-volume parts. It minimizes material waste and reduces lead times, enabling businesses to iterate quickly and efficiently. It also provides a reliable solution for on-demand manufacturing, bridging the gap between prototyping and large-scale production while maintaining cost-effectiveness.

Rapid Tooling

Rapid tooling combines rapid prototyping methods with normal tooling techniques to produce molds faster and more cost-efficiently. This concept helps to improve the efficiency of the bridge production stage continuously since it allows for changes in the design process, which don’t require huge amounts of resources.

Differences Between Bridge Production and Conventional Manufacturing

Bridge production is the phase of manufacturing before the large-scale approval and process. It comes as a means to mitigate the costs, mistakes, and shortfalls of going straight into full-scale production. The concept is different from the conventional manufacturing process in some ways.

In order to produce goods with continuous design changes, bridge manufacturing mostly depends on CNC machining and 3D printing technology. This manufacturing strategy lowers the risk associated with product launch and guarantees quicker lead times for product development. Without committing or spending a lot of money, product developers can produce small amounts of the components, get information from market research, and optimize the product design as needed.

Traditional manufacturing methods, on the other hand, include putting up production lines that are tailored for lengthy runs of a single product design.

Traditional approaches rely on economies of scale to reduce costs and use large machinery. More significantly, the drawback of these conventional approaches is their incapacity to adjust to shifting consumer preferences or market conditions without incurring exorbitant expenses.

Applications of Bridge Production

Many sectors benefit from the concept of bridge production by adopting it into their manufacturing plans. From saving costs on production waste to getting the most cost-efficient procedure for large-scale production, here are the applications of bridge production.

Consumer Electronics

In consumer electronics, the bridge manufacturing method enables corporations to test novel designs and features in electronic gadgets before investing in mass production. It allows customized gadgets or intricate features to be developed in response to specific client feedback without disrupting the entire production line.

Aerospace

The aerospace industry supports this technique for rigorous aerospace component design testing and refining, guaranteeing that it satisfies the high quality and reliability criteria. Aerospace businesses can use bridge production tactics to build fresh prototypes that mimic the final product’s features, allowing for thorough testing and verification processes.

醫療

In the medical field, the integration of sophisticated design and testing methodologies is vital for the development of medical devices and treatments. By using bridge production techniques, medical professionals can create models that allow for rigorous trials and evaluations. This process ensures that innovations are not only effective but also safe for patient use.

Automotive Industry

Within the automotive sector, there is a continuous pursuit of innovation through the design and testing of components. By leveraging bridge production techniques, manufacturers can craft prototypes that simulate real-world performance. This enables extensive testing that ensures safety, durability, and compliance with regulatory standards, ultimately leading to the production of vehicles that meet consumer expectations and enhance driving experiences.

How Bridge Production Supports Contract Manufacturing?

The client’s wants and product expectations are always changing; thus, contract manufacturing frequently involves a number of complications that seriously impede productivity. By utilizing manufacturing techniques and procedures, bridge production aids in successfully addressing these challenges.

Rapid prototyping technologies, which is a method used in bridge production to ensure that prototype iterations are completed quickly. For contract manufacturers who aim to create goods according to exact client specifications and promptly adjust to feedback, it is crucial. Prototypes can be produced in a matter of days by manufacturers using methods such as 3D printing and CNC machining.

Bridge production successfully aids in the creation of complex items without the need for costly molds or setups thanks to rapid manufacturing technologies. It is the perfect technology for custom manufacturing scenarios where unique or customized parts must be produced quickly.

Challenges and Considerations in the Bridge Production Process

Manufacturers have a number of challenges with the process, despite the fact that bridge production technology offers numerous advantages and flexibility. The following are some of this approach’s drawbacks and practical solutions.

Expensive to Start

Bridge production technology necessitates initial setup expenses due to the need for specific technologies and equipment, such as setup costs.

Consideration: To ensure a cost-effective procedure, it is advisable to do a thorough cost analysis in order to build a budget and evaluate financial help or subsidiaries. In order to attain economies of scale, it would also be beneficial to schedule longer production runs after the process has stabilized.

Complexities in the Supply Chain

Handling a supply chain with the flexibility required for bridge production frequently presents challenges and disruptions for manufacturers.

Consideration: Manufacturers can attain agility and quickly adapt to change by forming strategic alliances with leading suppliers and utilizing cutting-edge supply chain management software.

Problems with Synchronization

It can be challenging for designers and manufacturers to make sure that every stage of production is coordinated during the bridge-making process, particularly when switching from high mix low-volume manufacturing to mass production.

Consideration: To align all production phases, it would be beneficial to install strong project management software and procedures. Additionally, regular updates and cross-departmental meetings would assist in guaranteeing that every team is aware of the most recent advancements.

建議

如何避免加工過程中的機器碰撞?

Machine collision has always been an inevitable challenge in prototype and part machining. Operator errors, such as failing to perform tool settings, can lead to crashes. It will result in broken tools, scrapped workpieces, and reordering and reprocessing materials. In addition, without the automatic tool setter, manual tool setting when entering Z-value data error can also cause machine collision. In this article, we will share our summarized experiences to help you avoid this issue. Bef...

CNC Acrylic Machining: All You Need To Know Machined Acrylic Parts

Today we are going to look at the manufacturing processes of acrylic polymer or optical prototyping. It is one of the most widespread plastics all over the world and a prominent competitor to glass and polycarbonate. Due to the fact that acrylic parts are used in a lot of industry areas, it seems a good idea to look into its manufacturing processes, specifically CNC acrylic machining since that is the process that is present in almost any kind of acrylic production. In this article, we wi...

加工允許額解說:其計算方式及注意事項

加工余量是製造業的基本概念。它是 CNC 精密加工中常見的工程實務,可確保尺寸精度、表面品質,並生產可靠的功能性零件,適用於航空、國防和醫療等各種產業。本文嘗試回答這個問題:什麼是加工余量?我們將深入探討加工余量的概念,並討論為什麼機械師會留下加工余量?

All You Need To Know Engineering Drawing And Its Elements

Drawing or painting a picture is a great technique to convey one’s thoughts. Within the broad concept of industrial design, engineering drawing or technical drawing is an essential skill for designers working with the production of real objects. Therefore, engineering drawing is arguably one of the fundamentals of engineering design that serves several critical purposes. It is a standard technical drawing carrying essential design information, a mode of communication between different eng...

深圳市洗星科技有限公司

深圳市洗星科技有限公司