Causas y soluciones de las marcas de herramientas en el mecanizado de metales

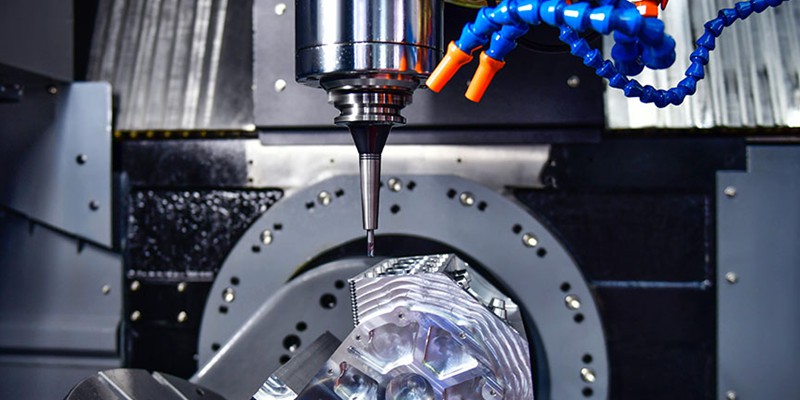

Precision metal parts are often manufactured using various precision machining technologies, with CNC machining being a common method. Usually, precision parts typically demand high standards for both dimensions and appearance.

Therefore, when using CNC machining metals such as aluminum and copper, the occurrence of tool marks and lines on the finished product’s surface is a concern. This article discusses the reasons that cause tool marks and lines during the machining of metal products. We also propose potential solutions.

Insufficient Clamping Force of Fixtures

Causes: Some cavity metal products need to use vacuum fixtures, and may struggle to generate sufficient suction due to the presence of surface irregularities, resulting in tool marks or lines.

Solution: To mitigate this, consider transitioning from simple vacuum suction to vacuum suction combined with pressure or lateral support. Alternatively, explore alternative fixture options based on specific part structures, tailoring the solution to the particular problem.

Process-related Factors

Causes: Certain product manufacturing processes may contribute to the issue. For instance, products like tablet PC rear shells undergo a sequence of machining steps involving punching side holes followed by CNC milling of the edges. This sequence can lead to noticeable tool marks when milling reaches the side-hole positions.

Solution: A common instance of this problem occurs when the aluminum alloy is chosen for electronic product shells. To resolve it, the process can be modified by replacing the side hole punching plus milling with only CNC milling. At the same time, ensuring consistent tool engagement and reducing uneven cutting when milling.

Inadequate Programming of Tool Path Engagement

Causes: This issue commonly arises during the 2D contour machining phase of product production. Poorly designed tool path engagement in the CNC program, leaving traces at the entry and exit points of the tool.

Solution: To address the challenge of avoiding tool marks at entry and exit points, a typical approach involves introducing a slight overlap in tool engagement distance (approximately 0.2mm). This technique serves to circumvent potential inaccuracies in the machine’s lead screw precision.

While this strategy effectively prevents the formation of tool marks, it causes an element of repetitive machining when the material of the product is a soft metal. Consequently, this section may exhibit variations in texture and color compared to other areas.

Fish Scale Patterns on Flat Machined Surfaces

Causes: Fish scale or circular patterns appearing on the product’s flat surfaces. The cutting tools used for processing soft metals such as aluminum/copper are generally alloy material mills with 3 to 4 flutes. They have a hardness ranging from HRC55 to HRC65. These milling cutting tools are performed using the bottom edge of the tool, and the part surface may develop distinctive fish scale patterns, impacting its overall appearance.

Solution: Commonly observed in products with high flatness requirements and flat surfaces featuring recessed structures. A remedy is to switch to cutting tools made from synthetic diamond material, which helps achieve smoother surface finishes.

Aging and Wear of Equipment Components

Causes: The tools mark on the product surface is attributed to the aging and wear of the equipment’s spindle, bearings, and lead screw. Additionally, inadequate CNC system backlash parameters contribute to pronounced tool marks, particularly when machining rounded corners.

Solution: These issues stem from equipment-related factors and can be addressed by targeted maintenance and replacement.

Conclusión

Achieving an ideal surface in the CNC machining metals demands useful approaches. There are different methods to avoid tool marks and lines that involve a combination of equipment maintenance, fixture enhancements, process adjustments, and programming refinements. By understanding and rectifying these factors, manufacturers can ensure that precision components not only meet dimensional criteria but also exhibit the desired aesthetic qualities.

Recomendaciones

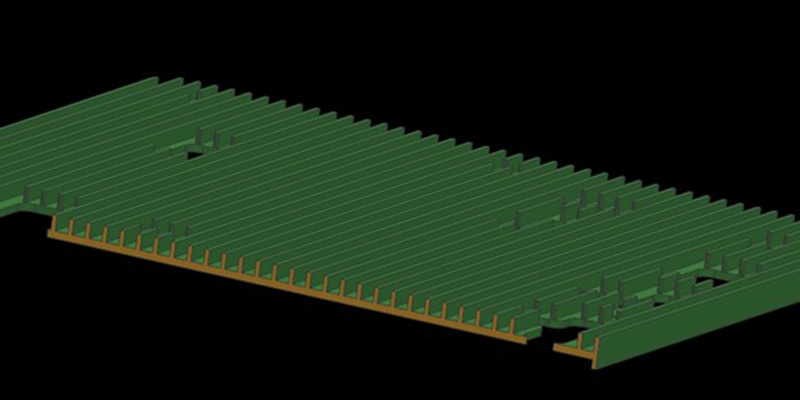

¿Cómo evitar el alabeo y la deformación de piezas grandes y de paredes delgadas durante el mecanizado CNC?

Las piezas de gran tamaño y paredes finas son fáciles de alabear y deformar durante el mecanizado. En este artículo, presentaremos un caso de disipador de calor de piezas grandes y de paredes finas para analizar los problemas en el proceso de mecanizado normal. Además, también ofrecemos una solución optimizada de proceso y utillaje. Manos a la obra El caso se refiere a una pieza en forma de concha fabricada en material AL6061-T6. Estas son sus dimensiones exactas. Dimensiones totales: 455*261.5*12.5mmEspesor de la pared de soporte: 2.5mmEspesor del disipador de calor: 1.5mm...

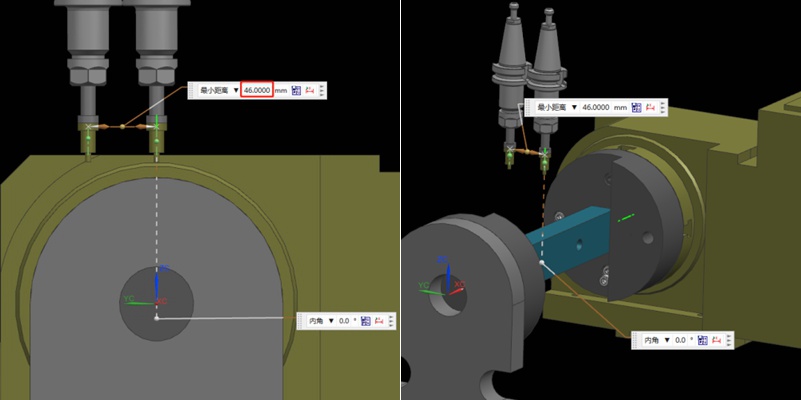

¿Cómo determinar el centro de rotación de rotación al operar una máquina CNC de 4 ejes?

Nowadays, a four-axis rotary table is a common piece of equipment in the machine shop. In order to complete the machining of multiple faces in one coordinate, the programming coordinates must be synchronized with the coordinates of the rotary table. In this article, we will share a method to determine the rotation center of a 4-axis rotary table.Here, we show a 4-axis rotary table that rotates around the X-axis of a machine tool, where the axis of rotation is called the A-axis. In a word,...

¿Cómo mecanizar piezas poliédricas de aluminio diseñando rutas de proceso y utillajes?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive considerations. In this article, Washxing provides an analysis of different process routes for polyhedral aluminum parts and compares the 3+2-axis CNC machining a...

Types Of Milling Explained: Know All Milling Operations

Milling is inarguably the backbone of the manufacturing industry, playing a direct role in high-quality production in industries including aerospace, automotive, medical, and defense. Milling operations are highly versatile and capable of handling complex geometries with precision and speed. In this article, we will discuss the fundamentals of CNC milling and explain various milling operations, helping to choose the right milling type for your applications.Milling is a machining process t...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd