¿Cómo mecanizar piezas poliédricas de aluminio diseñando rutas de proceso y utillajes?

Recomendaciones

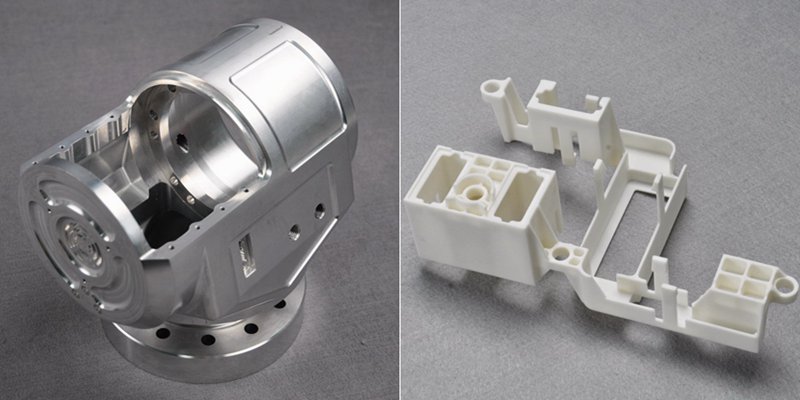

How To Create A Prototype With Steps: An Expert Guide

A prototype is an early version or physical model of a product idea that manufacturers can test and refine before investing in mass production. It acts as a product template and provides a practical approach to understanding a product’s appearance and function before production. When developing a product, product teams create a product prototype to test the product’s usability, design, and performance, gather user feedback, identify potential issues in the early stages, and identify possib...

Diseño de mecanizado CNC para fabricación: Guía técnica para expertos

Un diseño CNC eficiente es clave para equilibrar funcionalidad, coste y eficiencia de producción. Siguiendo estas directrices, puede evitar los problemas de diseño más comunes, mejorar la capacidad de fabricación y agilizar el proceso de producción. Desde minimizar las paredes finas y las cavidades profundas hasta establecer tolerancias razonables, cada recomendación de esta solución ayuda a simplificar el mecanizado al tiempo que garantiza la calidad. La profundidad de las cavidades y ranuras suele estar limitada por el diámetro de la herramienta de corte...

CNC Acrylic Machining: All You Need To Know Machined Acrylic Parts

Today we are going to look at the manufacturing processes of acrylic polymer or optical prototyping. It is one of the most widespread plastics all over the world and a prominent competitor to glass and polycarbonate. Due to the fact that acrylic parts are used in a lot of industry areas, it seems a good idea to look into its manufacturing processes, specifically CNC acrylic machining since that is the process that is present in almost any kind of acrylic production. In this article, we wi...

¿Cómo evitar la colisión de máquinas en el proceso de mecanizado?

Machine collision has always been an inevitable challenge in prototype and part machining. Operator errors, such as failing to perform tool settings, can lead to crashes. It will result in broken tools, scrapped workpieces, and reordering and reprocessing materials. In addition, without the automatic tool setter, manual tool setting when entering Z-value data error can also cause machine collision. In this article, we will share our summarized experiences to help you avoid this issue. Bef...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd