Comment éviter le gauchissement et la déformation des pièces à paroi mince et de grande taille lors de l'usinage CNC ?

Recommandations

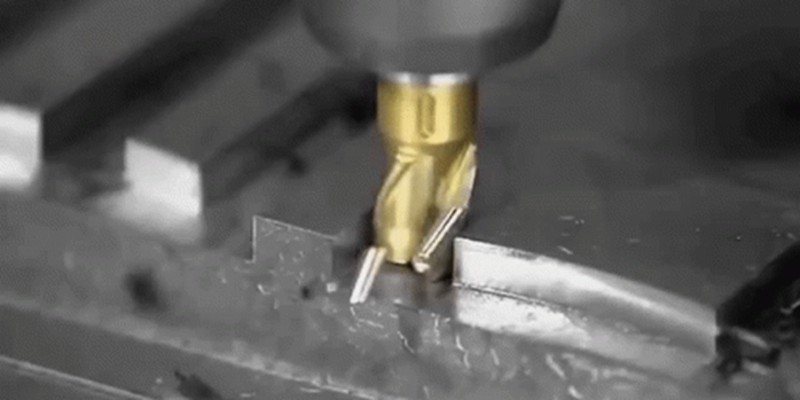

Causes et solutions pour les marques d'outils dans l'usinage des métaux

Les pièces métalliques de précision sont souvent fabriquées à l'aide de diverses technologies d'usinage de précision, l'usinage CNC étant une méthode courante. En général, les pièces de précision exigent des normes élevées en matière de dimensions et d'aspect. Par conséquent, lors de l'usinage CNC de métaux tels que l'aluminium et le cuivre, l'apparition de marques et de lignes d'outils sur la surface du produit fini est un problème. Cet article examine les raisons qui provoquent des marques et des lignes d'outil lors de l'usinage de produits métalliques....

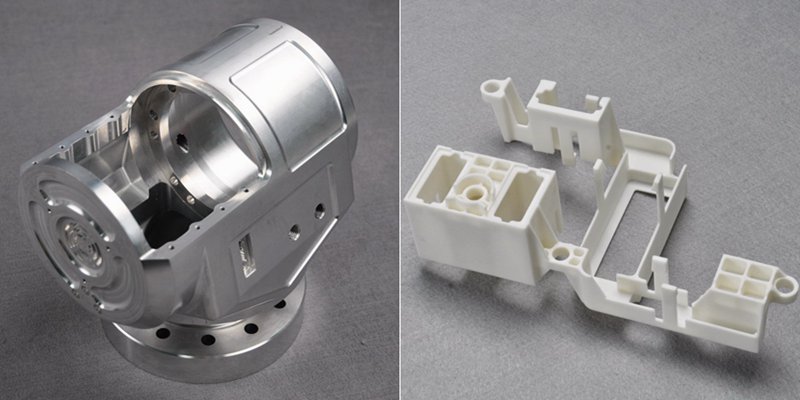

Conception de l'usinage CNC pour la fabrication : Guide technique d'expert

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!The depth of cavities and grooves is typically limited by the cutting tool diameter us...

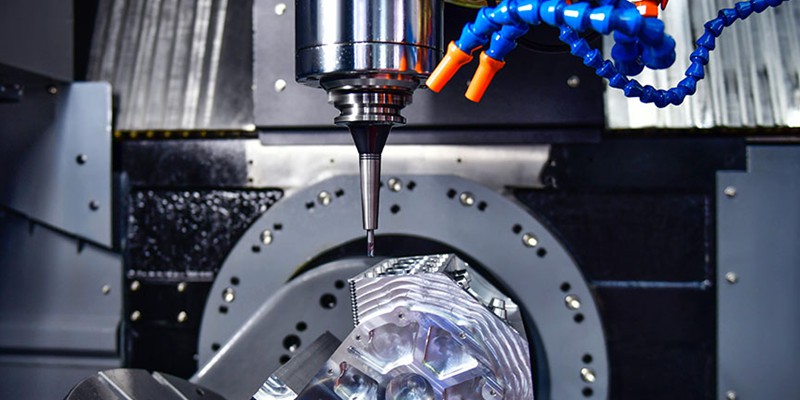

Types Of Milling Explained: Know All Milling Operations

Milling is inarguably the backbone of the manufacturing industry, playing a direct role in high-quality production in industries including aerospace, automotive, medical, and defense. Milling operations are highly versatile and capable of handling complex geometries with precision and speed. In this article, we will discuss the fundamentals of CNC milling and explain various milling operations, helping to choose the right milling type for your applications.Milling is a machining process t...

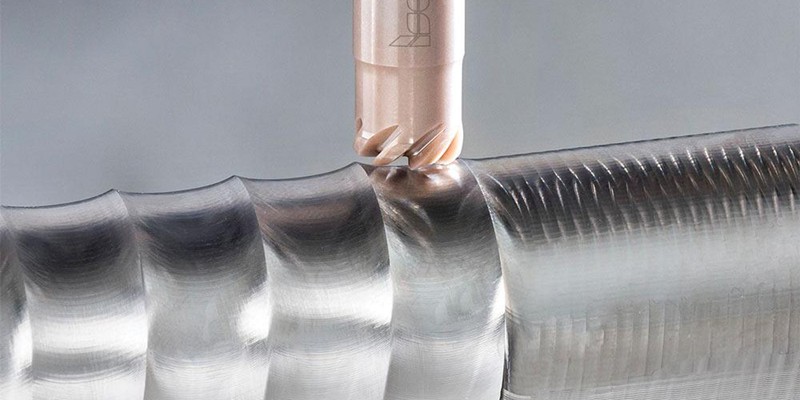

Machining Allowance Explained: Its Calculation And Matters

Machining allowance is a fundamental concept in manufacturing. It is a common engineering practice in CNC precision machining, ensuring dimensional accuracy, surface quality, and the production of reliable and functional components for a range of industries, including aerospace, defense, and medical. This article attempts to answer the question: what is machining allowance? We will take a deep dive into the concept of machining allowance and discuss why machinists leave machining allowanc...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd