Comment éviter le gauchissement et la déformation des pièces à paroi mince et de grande taille lors de l'usinage CNC ?

Recommandations

Usinage CNC de l'acrylique : Tout ce que vous devez savoir Pièces usinées en acrylique

Aujourd'hui, nous allons nous pencher sur les processus de fabrication du polymère acrylique ou prototypage optique. Il s'agit de l'un des plastiques les plus répandus dans le monde et d'un concurrent important du verre et du polycarbonate. Étant donné que les pièces en acrylique sont utilisées dans de nombreux secteurs industriels, il semble judicieux de se pencher sur ses processus de fabrication, en particulier l'usinage CNC de l'acrylique, car c'est le processus qui est présent dans presque tous les types de production d'acrylique. Dans cet article, nous...

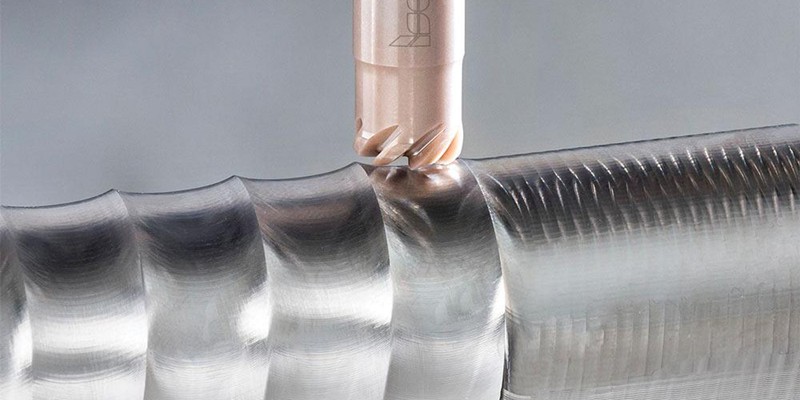

What Is SFM? A Complete Guide To Surface Feet Per Minute In Machining

SFM, meaning Surface Feet per Minute in CNC machining, measures how fast a cutting tool moves across a workpiece. It is expressed in feet per minute. SFM combines the tool or workpiece diameter with the spindle speed (RPM). A larger diameter or higher RPM results in a higher SFM. Machinists use surface feet per minute to determine the best cutting speed for a material. Different materials have recommended SFM values for optimal performance. For example, 303 annealed stainless steel has an...

Machining Allowance Explained: Its Calculation And Matters

Machining allowance is a fundamental concept in manufacturing. It is a common engineering practice in CNC precision machining, ensuring dimensional accuracy, surface quality, and the production of reliable and functional components for a range of industries, including aerospace, defense, and medical. This article attempts to answer the question: what is machining allowance? We will take a deep dive into the concept of machining allowance and discuss why machinists leave machining allowanc...

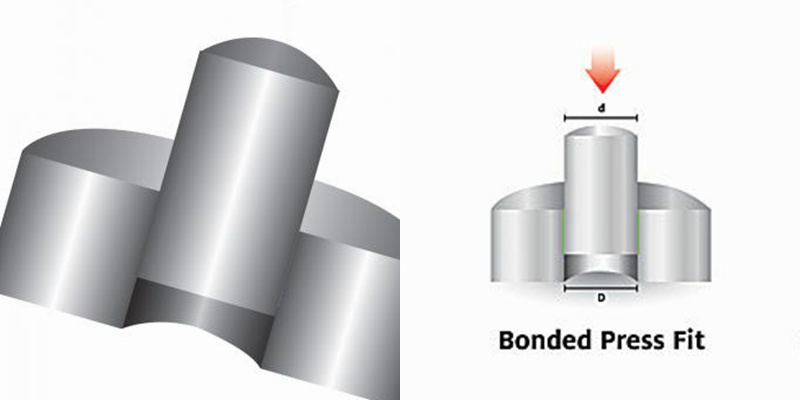

Press Fit Tolerance: Defination, Practices, And Calculation

The manufacturing industry is highly precision-centric, where even the slightest of margins can create huge differences in product quality, cost, and utility. This article discusses the topic of press fitting, where a few micrometers of deviation dictates the criterion for part failure. So, what is press fit and, the factors influencing press fit tolerancing, and present an example of a press fit calculator. We will also share some key tips to keep in mind while designing components for p...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd