Wie bearbeitet man polyedrische Aluminiumteile durch die Entwicklung von Prozessrouten und Vorrichtungen?

Empfehlungen

CNC-Bearbeitung - Entwurf für die Fertigung: Technischer Leitfaden für Experten

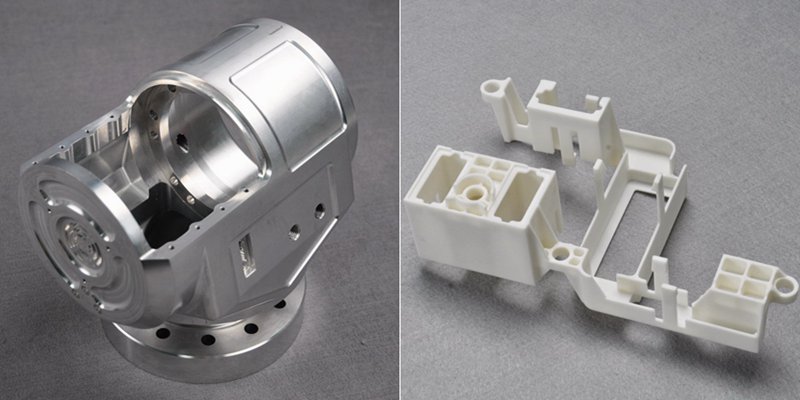

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution helps simplify machining while ensuring quality. Let’s get to it!The depth of cavities and grooves is typically limited by the cutting tool diameter us...

CNC Acrylic Machining: All You Need To Know Machined Acrylic Parts

Today we are going to look at the manufacturing processes of acrylic polymer or optical prototyping. It is one of the most widespread plastics all over the world and a prominent competitor to glass and polycarbonate. Due to the fact that acrylic parts are used in a lot of industry areas, it seems a good idea to look into its manufacturing processes, specifically CNC acrylic machining since that is the process that is present in almost any kind of acrylic production. In this article, we wi...

Produktion und Herstellung von Brücken: Wichtige Etappen und Vorteile

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable manufacturing process is developed. Understanding bridge production is crucial for enhancing product development and expediting operations. This article...

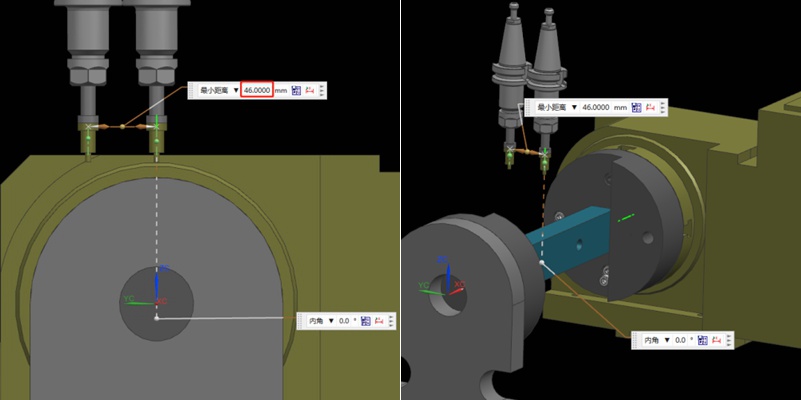

Wie bestimmt man das Rotationszentrum eines Rotationskörpers beim Betrieb einer 4-Achsen-CNC-Maschine?

Heutzutage ist ein vierachsiger Rundtisch ein gängiges Gerät in der Maschinenwerkstatt. Um die Bearbeitung mehrerer Flächen in einer Koordinate abschließen zu können, müssen die Programmierkoordinaten mit den Koordinaten des Rundtisches synchronisiert werden. In diesem Artikel wird eine Methode zur Bestimmung des Rotationszentrums eines 4-Achsen-Rundtisches vorgestellt: Ein 4-Achsen-Rundtisch, der sich um die X-Achse einer Werkzeugmaschine dreht, wobei die Drehachse als A-Achse bezeichnet wird. Mit einem Wort,...

ShenZhen Washxing Technology Co.,Ltd

ShenZhen Washxing Technology Co.,Ltd