Teknik Çözümler

Outdoor cameras are essential for enhancing the security and monitoring of outdoor spaces.

These devices are designed to withstand various weather conditions, ensuring reliable performance in rain, snow, and extreme temperatures.

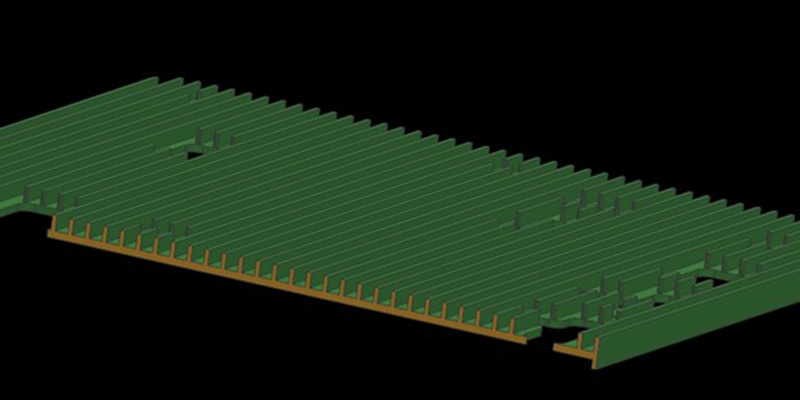

CNC İşleme Sırasında Büyük ve İnce Duvarlı Kabuk Parçalarda Çarpılma ve Deformasyon Nasıl Önlenir?

Large, thin-walled shell parts are easy to warp and deform during machining. In this article, we will introduce a heat sink case of large and thin-walled parts to discuss the problems in the regular machining process. In addition, we also provide an optimized process and fixture solution. Let’s get to it! The case is about a shell part made...

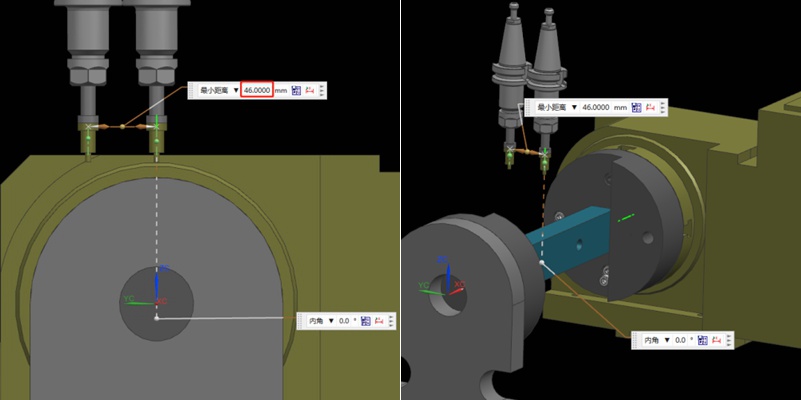

Bir 4 Eksenli CNC Makinesi Çalıştırırken Döner Dönme Merkezi Nasıl Belirlenir?

Nowadays, a four-axis rotary table is a common piece of equipment in the machine shop. In order to complete the machining of multiple faces in one coordinate, the programming coordinates must be synchronized with the coordinates of the rotary table. In this article, we will share a method to determine the rotation center of a 4-axis rotary t...

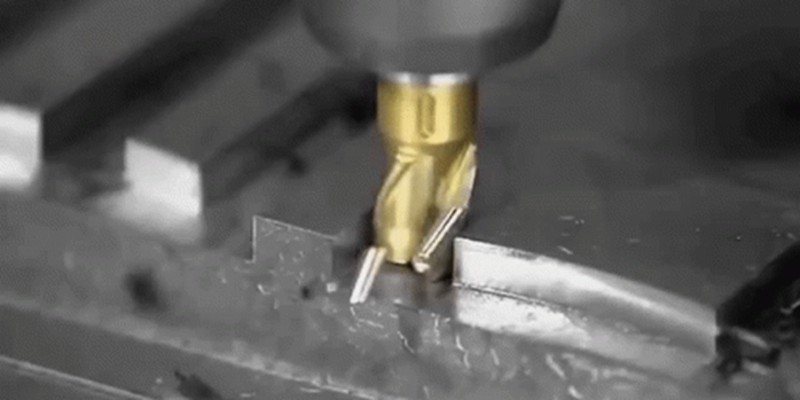

Metal İşlemede Takım İzlerinin Nedenleri ve Çözümleri

Precision metal parts are often manufactured using various precision machining technologies, with CNC machining being a common method. Usually, precision parts typically demand high standards for both dimensions and appearance. Therefore, when using CNC machining metals such as aluminum and copper, the occurrence of tool marks and lines on t...

İşleme Sürecinde Makine Çarpışması Nasıl Önlenir?

Machine collision has always been an inevitable challenge in prototype and part machining. Operator errors, such as failing to perform tool settings, can lead to crashes. It will result in broken tools, scrapped workpieces, and reordering and reprocessing materials. In addition, without the automatic tool setter, manual tool setting when ent...

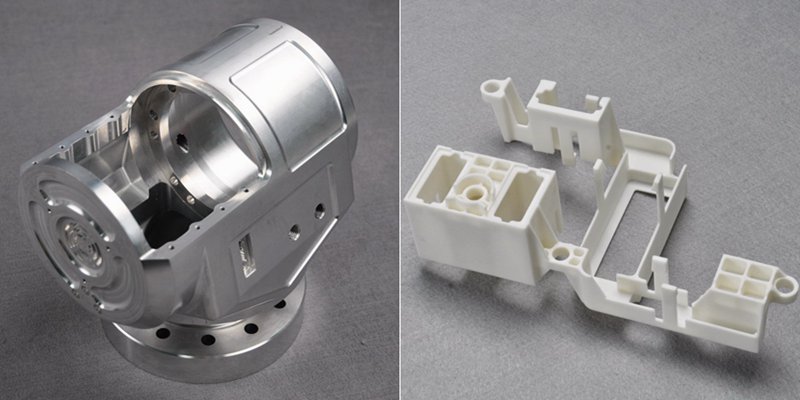

Proses Rotaları ve Fikstür Tasarlayarak Çok Yüzlü Alüminyum Parçalar Nasıl İşlenir?

In the field of machining and manufacturing, selecting the appropriate machining strategy is important for improving production efficiency. In common, the polyhedral machined parts have complex geometries and tight tolerance requirements. So how choosing a suitable processing route for machining such parts requires comprehensive consideratio...

Üretim için CNC İşleme Tasarımı: Uzman Teknik Kılavuz

Efficient CNC design is key to balancing functionality, cost, and production efficiency. By following these guidelines, you can avoid common design challenges, improve manufacturability, and streamline the production process. From minimizing thin walls and deep cavities to setting reasonable tolerances, each recommendation in this solution h...

Köprü Üretimi ve İmalatı: Temel Aşamalar ve Faydalar

Adopting a final production process often involves numerous trials and failures, particularly during prototyping or low-volume production. Companies may temporarily select a production method until they are confident in their approach. Bridge production refers to this temporary strategy, enabling continued operations while a more reliable ma...

Adım Tornalama vs Konik Tornalama: Farklar Nelerdir?

Turning is a fundamental machining operation that has supported the manufacturing industry for centuries. It continues to evolve and is a core manufacturing technique to this day. This article will discuss two types of turning operations: step turning vs taper turning. We will explore the step process and taper turning process and explain t...

ShenZhen Washxing Technology Co, Ltd

ShenZhen Washxing Technology Co, Ltd